A slip coupler 22mm is one of those essential bits of kit in hydraulic systems, especially on mobile machinery. Think of it as a heavy-duty quick-release connector. Its whole purpose is to let you connect and disconnect fluid lines in a flash, usually with a simple push-pull motion. This saves a massive amount of time when you're swapping out attachments.

What a 22mm Slip Coupler Actually Does

Picture a high-pressure hydraulic system. Now, imagine needing to swap attachments on a tractor or an excavator. The 22mm slip coupler is the component that makes this a quick, clean job instead of a slow, messy one. It’s engineered to create a secure, leak-proof link between hydraulic lines that can be broken and remade in seconds, often without even shutting the machine down.

This clever little device is designed to solve two of the biggest headaches in hydraulics: losing precious fluid and letting dirt into the system.

For anyone working in UK agriculture or construction, this is a game-changer. When you're switching from a plough to a baler, or from a bucket to a breaker, every minute counts. The ‘slip’ or ‘push-pull’ design means these changes are done in moments, not hours, which is a huge boost to efficiency.

Core Functions and Benefits

At its heart, the design of a 22mm slip coupler is all about speed and reliability. Inside each half of the coupler is a valve. When you disconnect the lines, these valves snap shut instantly, trapping the hydraulic fluid inside. No spills, no mess, no hazards.

When you push the two halves back together, the valves open up, allowing the fluid to flow freely with very little restriction.

This brings some major advantages to the table:

- Less Downtime: Quick changes mean your machinery is out there earning its keep, not sitting in the yard being reconfigured.

- Protects Your System: By sealing the lines, the coupler keeps dirt, dust, and water from getting into your sensitive hydraulic system. This protects expensive pumps, valves, and cylinders from damage.

- Safer Working Environment: With no fluid spills, there's less risk of slips and falls on site, and it's much better for the environment.

- Makes Your Machine More Versatile: Operators can easily swap between a whole range of hydraulic tools, making a single tractor or digger far more useful.

A Key Component in UK Mobile Hydraulics

You'll find these couplers everywhere for a good reason. In the UK hydraulics market, which is worth around £1.3 billion, the mobile sector is the biggest player, making up over 59% of that. Within that, components like the 22mm slip coupler are absolutely essential.

Think about agriculture alone. With over 250,000 tractors working in the UK, these couplers can speed up maintenance and attachment changes by as much as 40%. In an industry where costs are always rising, that kind of efficiency gain is huge. You can dive deeper into these market stats over on Grand View Research.

So, the 22mm slip coupler isn't just a simple connector; it’s a small piece of engineering that makes a big difference in productivity.

For expert advice on selecting the right hydraulic components for your system, phone 01724 279508 today, or send us a message at https://www.mahydraulics.co.uk/contact-us/.

Real-World Applications: Where 22mm Slip Couplers Shine in UK Industry

It's one thing to understand the mechanics of a 22mm slip coupler, but it's another to see where it truly makes a difference. These clever components are the unsung heroes in countless UK industries, tackling everyday challenges and keeping operations running smoothly. You'll find them anywhere speed, flexibility, and reliability are paramount.

Their use really boils down to two main arenas: the rough and tumble world of mobile machinery out on farms and building sites, and the precision-driven environment of factories and industrial plants. In both worlds, the coupler’s knack for enabling quick changes is what makes it so valuable.

On the Move: Mobile Machinery

Think about any modern farm or construction site. A single machine, be it a tractor or an excavator, is expected to be a jack-of-all-trades. The slip coupler 22mm is the secret sauce that makes this possible, letting operators swap hydraulic attachments in a flash.

Agriculture: A tractor is the perfect example. One minute it's pulling a hydraulic plough, the next it’s powering a complex seed drill or a hay baler. Slip couplers on the hydraulic lines mean an operator can unhook one tool and attach another in minutes. This is all done without spilling significant amounts of hydraulic fluid or, just as importantly, letting dirt and field debris into the clean hydraulic system.

Construction: It's a similar story on a building site. An excavator needs to swap from a digging bucket to a hydraulic breaker, then maybe to a grapple. Each of these attachments has unique hydraulic demands. A 22mm slip coupler provides the fast, leak-free connection needed to keep the job on schedule, which is absolutely vital when you're up against tight deadlines.

The UK's hydraulic hose market is valued at around £138 million and is expected to grow, which tells you just how vital components like 22mm slip couplers are. With construction projects surging by billions of pounds recently, the demand for adaptable hydraulic systems has never been higher. These couplers are essential for routing hoses through the incredibly tight confines of modern diggers and loaders. You can dig deeper into this data in this market research report.

In the Factory: Industrial and Production Lines

Step inside a factory, and the challenges change, but the solution often stays the same. Here, the game is all about production uptime and how quickly you can perform maintenance.

A 22mm slip coupler is a common sight on modular production lines. When a line needs to be switched over for a different product run, hydraulic tools, clamps, or presses can be swapped out easily. This means a factory can reconfigure an entire assembly line without calling in specialist engineers to start cutting and re-fitting pipework.

You'll also see them on materials handling gear. Forklifts fitted with hydraulic clamps or rotators rely on these couplers to make maintenance a breeze. If a hydraulic part fails, it can be disconnected and swapped out in minutes, drastically cutting down on machine downtime and keeping warehouse logistics flowing.

If you need a hand choosing the right slip coupler for your machinery, give our experts a ring on 01724 279508, or send us a message through our contact form.

How to Choose the Right 22mm Slip Coupler

Picking the right 22mm slip coupler is about more than just finding one that fits. It's a decision that directly impacts the safety of your operators, the lifespan of your machinery, and the overall efficiency of your hydraulic system. Getting it right from the start helps you avoid expensive downtime and unexpected component failures down the road.

To make the best choice, you need to dig into the technical details and see how they stack up against what your system actually needs, whether it's powering a combine harvester or a heavy press on a factory floor.

Understanding Material and Pressure Ratings

First things first, let's talk about what the coupler is made of. The vast majority are built from carbon steel, and for good reason—it’s tough, reliable, and cost-effective. This makes it the go-to choice for general agricultural and construction machinery. But what if your equipment is constantly exposed to the elements or works with corrosive fluids? In that case, you’ll want to look at stainless steel options, which offer far better protection against rust and chemical damage.

Next up, and this is a big one, are the pressure ratings. You’ll see two critical figures for any coupler:

- Working Pressure: Think of this as the coupler's daily speed limit. It’s the maximum pressure it can safely handle day in, day out during normal operations. Your system’s pressure should never exceed this number.

- Burst Pressure: This is the absolute failure point. While it’s usually several times higher than the working pressure, it's a safety margin, not a target. Pushing a system anywhere near its burst pressure is asking for trouble.

Making sure these ratings align with your hydraulic system’s own specifications is absolutely essential for safe and reliable operation.

Matching Flow Rate and Seal Compatibility

A coupler's flow rate capacity is just as crucial. Imagine trying to empty a swimming pool through a garden hose—it’s just not going to work efficiently. If your coupler can't handle the volume of hydraulic fluid your pump is pushing, it creates a bottleneck. This resistance generates excess heat, wastes energy, and ultimately hurts your system's performance. Always select a slip coupler 22mm with a flow rate that can comfortably handle what your system delivers.

The final piece of this puzzle is the seal material. These small internal seals are what keep the hydraulic fluid where it's supposed to be, so their composition matters. The most common material is Nitrile (NBR), which is perfect for systems running on standard mineral-based hydraulic oils. However, if you're using synthetic fluids, dealing with high temperatures, or exposing the system to aggressive chemicals, you’ll need a more resilient material like Viton (FKM) to prevent the seals from degrading and causing leaks. For a closer look at various high-quality options, you can explore the OMT Group ND500 series on our website.

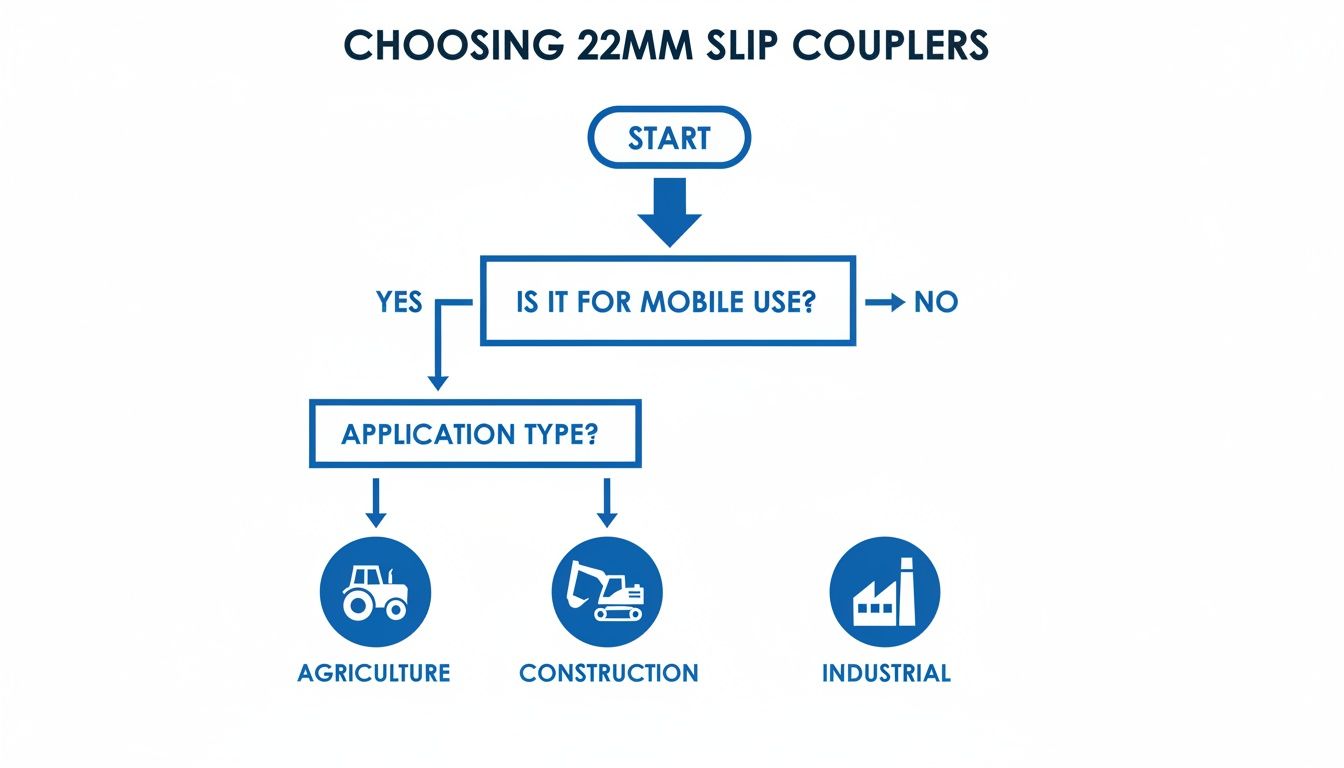

To simplify the selection process, this flowchart outlines a basic decision-making path based on your primary application.

As the chart shows, figuring out whether your machinery is mobile or industrial is the first fork in the road, helping you narrow down the field to find the perfect component.

The table below breaks down the key specifications to consider when weighing your options.

22mm Slip Coupler Specification Checklist

| Specification | What to Consider | Typical Options | Application Example |

|---|---|---|---|

| Material | Is the environment corrosive? Will it be exposed to harsh weather? | Carbon Steel, Stainless Steel | A stainless steel coupler for a marine winch exposed to saltwater. |

| Working Pressure | What is the maximum continuous pressure of your hydraulic system? | 250 – 350 bar | An agricultural tractor's hydraulic system operating at 210 bar. |

| Flow Rate | What is the pump's output in litres per minute (LPM)? | 60 – 120 LPM | A log splitter requiring a flow of 75 LPM for efficient operation. |

| Seal Material | What type of hydraulic fluid are you using? Are high temperatures a factor? | Nitrile (NBR), Viton (FKM) | A system with high-temperature synthetic fluid needing Viton seals. |

Considering each of these factors will ensure you get a coupler that not only fits but performs reliably for years to come.

If you need some expert help choosing the perfect 22mm slip coupler, give us a call on 01724 279508 today, or send us a message via our contact page.

Step-By-Step Installation and Troubleshooting

Getting a slip coupler 22mm fitted correctly is about more than just avoiding a mess; it's fundamental to the safety and performance of your entire hydraulic system. A methodical approach is your best defence against leaks, contamination, and premature component failure. Let's walk through the practical steps for a clean installation and how to diagnose those common issues that crop up in the field.

Before a single tool is picked up, think safety. Always get your personal protective equipment (PPE) on, especially safety glasses and gloves. You must ensure the hydraulic system is fully shut down and—this is critical—relieve any trapped pressure lingering in the lines.

A Guide to Correct Installation

Doing the job right the first time will save you endless headaches down the road. Start with a clean workspace. It’s not just about being tidy; even a tiny speck of grit can cause serious damage to sensitive hydraulic components.

For a secure, leak-free connection, follow these steps:

- Clean Everything: Give the male and female ends of the coupler and any hose fittings a thorough wipe-down. Use a clean, lint-free cloth to get rid of any dirt, grease, or debris.

- Inspect Seals and Threads: Before you connect anything, give the O-rings and threads a quick visual check. You're looking for any nicks, cuts, or damage that could stop it from sealing properly.

- Apply Thread Sealant: If you're working with tapered threads, apply a suitable thread sealant or PTFE tape. Make sure to apply it correctly—just a few wraps in the direction of the thread—to prevent bits from breaking off and contaminating the hydraulic fluid.

- Tighten Correctly: Screw the fittings together by hand until they feel snug. After that, grab the right size spanners and tighten them to the manufacturer's recommended torque. It's a fine balance; over-tightening can wreck threads and seals, but under-tightening is a guaranteed leak.

It's a common myth that tighter is always better. In hydraulics, over-torquing fittings is one of the leading causes of component failure. It can crack ports and strip threads in a heartbeat. Always stick to the specified torque values for a connection that’s secure but not stressed.

Troubleshooting Common Coupler Issues

Even after a textbook installation, things can sometimes go wrong during operation. Being able to spot the cause quickly is the key to minimising downtime and getting your equipment back to work.

Here are a few frequent problems and what they usually point to:

- Problem: Coupler Won't Connect: Nine times out of ten, this is because of trapped pressure in the hydraulic line. The first thing to do is make sure all pressure has been safely relieved. If that’s not the issue, check for dirt or debris physically blocking the connection mechanism.

- Problem: Persistent Leaks: If the coupler is weeping fluid when connected, the most likely culprits are damaged or worn internal seals, like the O-rings. Mismatched or damaged threads are another possibility. Disconnect the coupler, inspect everything again, and replace any seals that look compromised. Sometimes, you might need other parts like port adaptors to get a perfect fit; you can learn more about our range of port adaptors here.

- Problem: Restricted Fluid Flow: Does the system seem sluggish or weak after fitting the new coupler? It might not be fully engaged. Try disconnecting and reconnecting it, listening for that satisfying 'click' that tells you it's locked in place. In more serious cases, severe contamination could be clogging the internal valves and choking the flow.

By keeping these installation and troubleshooting tips in mind, you can make sure your slip coupler 22mm gives you the reliable and efficient service life your machinery depends on.

For expert advice on hydraulic components or troubleshooting, give us a call on 01724 279508 today, or send a message through our contact page.

Getting More Life Out of Your Hydraulic Couplers

When it comes to hydraulic components, a little preventative maintenance goes a very long way, and the slip coupler 22mm is no different. A few simple, regular checks can be the difference between a smooth-running machine and a costly failure. This isn't just about ticking boxes; it's about boosting reliability and avoiding that dreaded downtime that always seems to hit at the worst possible moment.

Your first line of defence is a consistent inspection schedule. It doesn't have to be complicated. Just a quick visual check before each use can catch a problem before it escalates. Get into the habit of looking for the obvious signs of trouble before you connect or disconnect any lines.

What to Look for During Inspections

When you’re looking over a 22mm slip coupler, you’re hunting for anything that could stop it from creating a perfect seal or operating smoothly. A tiny issue today can easily become a major leak tomorrow.

Here’s a quick checklist to run through:

- Physical Damage: Scan the coupler body for any dents, cracks, or deep scratches. A hard knock can easily distort the internal mechanism and stop it from connecting or sealing properly.

- Signs of Corrosion: Keep an eye out for rust or pitting, a common enemy for carbon steel couplers. Corrosion doesn't just look bad; it weakens the material and can cause the push-pull sleeve to seize up.

- Worn Seals: Visually check any seals you can see. Are they cracking, swelling, or looking flattened? A failing seal is the number one culprit behind those persistent, slow leaks.

- Damaged Threads: Make sure the threads are clean and sharp. If they’re crossed or damaged, you’ll never get a secure connection, and you’re just asking for a leak.

If you take away one thing, let it be this: keeping your couplers clean is the single most important maintenance task you can perform. Dirt, grit, and water are the sworn enemies of any hydraulic system, and the coupler is a primary gateway for them to get in.

The Importance of Cleanliness

It’s a simple rule: a clean coupler is a reliable coupler. Always, always wipe both the male and female ends with a clean, lint-free cloth before you make a connection. This two-second action stops dirt from being pushed into the system, where it can wreck sensitive valves and pumps.

Using dust caps and plugs on your disconnected lines is non-negotiable. They are a cheap and incredibly effective way to shield the coupler’s internals from contamination and damage. When you’re not using your hoses, cap the ends and hang them up—don't let them drag on the floor collecting debris.

Properly maintained 22mm slip couplers are a cornerstone of the UK's Fluid Power Equipment Manufacturing industry, a sector pulling in revenues of over £1.3 billion. In custom-built hydraulic power packs, these well-kept components can slash leak incidents by more than 25% compared to older fitting types, making them a real asset for efficiency. You can find more insights on this vital UK industry over at IBISWorld.

For some expert advice on keeping your hydraulic components in top shape, give us a call on 01724 279508 today, or drop us a message at https://www.mahydraulics.co.uk/contact-us/.

Got Questions About 22mm Slip Couplers? We’ve Got Answers.

Even when you know the basics, practical questions always pop up in the workshop or during system design. Let's tackle some of the most common queries we get from engineers and technicians in the field, clearing up any confusion about using a slip coupler 22mm.

Think of this as your go-to guide for the nitty-gritty details. Getting these right can be the difference between a smooth-running system and a frustrating day on site.

Can I Connect a Slip Coupler Under Full Pressure?

The short answer is a definite no. Standard slip couplers are not built to be connected or disconnected when the hydraulic system is fully pressurised.

Attempting to force a connection against that kind of pressure is not just difficult; it's incredibly dangerous. You risk high-velocity fluid jets and you’ll almost certainly wreck the coupler’s internal valves and seals. Always relieve any trapped pressure in the line before you try to connect or disconnect. Specialised 'connect-under-pressure' couplers do exist, but they are a distinct product, so never assume a standard coupler has this feature unless the spec sheet explicitly says so.

What’s the Real Difference Between a Slip Coupler and a Flat-Face Coupler?

It really comes down to their design and where they shine. A slip coupler 22mm is what’s known as a poppet-style coupler, using a simple and tough push-pull mechanism. This makes it a workhorse for agricultural and mobile machinery, where you need fast connections and something that can take a beating in dirty conditions.

Flat-face couplers, by contrast, are all about precision and cleanliness. Their design is engineered to prevent fluid spillage when you disconnect and to stop dirt from getting trapped on the mating surfaces. This is why you’ll find them in sensitive environments like food processing plants or indoor industrial hydraulics, where even a tiny bit of contamination is a major problem.

How Do I Know Which Coupler Works with My Hydraulic Fluid?

This is all about the seals. The material of the internal seal inside the coupler must be chemically compatible with your hydraulic fluid. If it isn't, the seal will eventually swell, go brittle, or simply fail, leading to leaks.

Here’s a simple rule of thumb:

- Nitrile (NBR) is the industry standard. It’s perfect for the vast majority of systems running on mineral-based hydraulic oils.

- Viton (FKM) is what you need for more demanding applications. Think synthetic fluids, systems that run very hot, or those using more aggressive chemicals.

Your best bet is to always cross-reference the fluid’s safety data sheet with the coupler's technical specifications. A quick check here saves a world of trouble later on.

For expert help with any hydraulic component queries, phone 01724 279508 today, or send us a message.

Get the Right Hydraulic Components from MA Hydraulics

Picking out and looking after the right 22mm slip coupler isn’t just a tick-box exercise; it’s absolutely vital for keeping your hydraulic system running safely and efficiently. As we’ve covered in this guide, it's the small details that make all the difference—from the material and pressure rating right through to simple, regular maintenance checks. Get this stuff right, and your machinery will thank you with reliable, effective performance.

Here at MA Hydraulics, we do more than just shift boxes. We’re here to share our expertise and make sure you walk away with the perfect component for your exact setup. Our team has years of hands-on experience, and we back it up with a massive stock of top-quality hydraulic parts from brands we know and trust.

Your Partner in Hydraulic Solutions

Need a single replacement fitting to get a machine back online fast? We've got you. Designing a completely bespoke hydraulic power pack from scratch? We can help with that too. We understand the pressures you're under and make it our business to provide solutions that work hard and deliver real value for years to come.

For a deeper dive into the technical specs of our range, feel free to check out our detailed OMT bellhousing and couplings accessories guide.

We've always believed that giving the right advice is just as crucial as supplying the right part. Our goal is to be a partner you can count on, helping you build systems that are efficient, safe, and built to last.

From helping you choose the best component at the start to providing support long after the sale, we’re genuinely invested in your success. You can expect competitive pricing, quick turnarounds, and the friendly, knowledgeable service our customers know they can rely on.

For expert advice on what your hydraulic system needs, fair pricing, and dependable service, please don't hesitate to get in touch. Phone 01724 279508 today, or send us a message at https://www.mahydraulics.co.uk/contact-us/.