Think of the hydraulic cylinder piston as the real muscle behind the entire system. It's the key component that takes the energy from pressurised fluid and turns it into raw, mechanical force.

In many ways, it works just like a plunger in a syringe. The piston sits snugly inside the cylinder bore and is pushed along by hydraulic fluid. This movement extends a rod that can then lift, push, or pull with incredible strength.

What a Piston Actually Does Inside a Hydraulic Cylinder

At its heart, the piston's job is straightforward but immensely powerful. It serves as a moving barrier inside the cylinder barrel, creating two separate chambers.

When high-pressure fluid is pumped into one of these chambers from a hydraulic power unit, it presses against the piston's face, forcing it to slide along the bore. This simple linear motion is what powers everything from construction diggers to factory presses across the UK.

The whole process hinges on a fundamental law of physics: Force = Pressure × Area. This elegant formula tells us that the force a cylinder produces is a direct result of the fluid pressure multiplied by the surface area of the piston.

Putting the Force Equation to Work

Let's make this real. Imagine you have a piston with a surface area of 30 square centimetres. If the system is running at a pressure of 200 bar (that's about 20 megapascals), the force it generates is massive. It’s more than enough to move seriously heavy loads with pinpoint control.

This simple calculation underpins the design and performance of nearly every piece of hydraulic machinery, from agricultural tractors to mobile cranes. It also shows why the piston's dimensions are so important:

- A piston with a larger surface area will generate more force at the same pressure.

- A smaller piston will produce less force, but it can often move much faster.

The piston is the central actor in all hydraulic motion. It's not just a passive part; it's what actively converts the potential energy stored in pressurised fluid into the kinetic energy that gets the job done. Without it, the system is just a collection of pipes and oil.

The piston's movement is precisely controlled by directing the flow of fluid from the hydraulic power pack. The entire assembly—cylinder, piston, and fluid—works in perfect harmony to deliver a powerful and controllable output. That’s why getting to grips with the hydraulic cylinder piston is the first step towards mastering the operation, maintenance, and repair of any hydraulic system.

For expert advice on specifying, sourcing, or manufacturing a hydraulic cylinder piston for your application, phone us on 01724 279508 today, or send a message to our team at https://www.mahydraulics.co.uk/contact-us/.

A Closer Look at Different Hydraulic Piston Designs

When it comes to hydraulic cylinder pistons, there's no such thing as a one-size-fits-all solution. The design of a piston is meticulously chosen to match the specific job it needs to do, dictating everything from its raw power to its operational precision. Different applications demand different designs, each bringing its own strengths and trade-offs to the table.

Getting to grips with these variations is essential for anyone working in hydraulic system design, maintenance, or repair. The choice between a simple, rugged piston and a more complex, serviceable one can have a huge impact on a cylinder’s efficiency, its lifespan, and how easily it can be maintained down the line.

At its core, the piston's job is straightforward: it converts the pressure of hydraulic fluid into raw mechanical force.

This diagram shows that simple principle in action. The piston is the critical component that turns the stored energy in the fluid into the kinetic energy that gets the work done.

Single-Piece Piston Designs

The most straightforward and often most robust option is the single-piece piston. As the name suggests, it's machined from a solid block of steel or ductile iron. This design is incredibly strong, with no separate parts that could work loose or fail under pressure. Its solid construction makes it the go-to choice for high-pressure, heavy-duty work where absolute reliability is non-negotiable.

You'll typically find single-piece pistons in the toughest environments:

- Construction Equipment: Think excavator arms and bulldozer blades that have to withstand enormous shock loads.

- Agricultural Machinery: Tractor loaders and hydraulic presses need simple, powerful force, and this design delivers.

- Industrial Presses: Machinery performing repetitive, high-force stamping or moulding jobs relies on this durability.

The main draw here is sheer strength. The flip side? If the seal grooves get damaged, you're looking at replacing the entire piston, which can be a costly affair. Repairing the sealing surfaces just isn't a practical or economical option in most cases.

Two-Piece Piston Designs

For applications that demand a bit more finesse or easier long-term maintenance, the two-piece piston design is a common choice. This construction usually features a main piston body with a separate retainer plate or locking nut. This arrangement securely clamps the seals and wear bands into place.

The real advantage of a two-piece design is serviceability. When a seal eventually fails or the wear bands need changing, the piston can be taken apart, fitted with fresh components, and put back together. This makes routine maintenance far more cost-effective, as you avoid having to scrap the whole piston assembly. It also opens the door for more complex seal arrangements, which can boost performance in high-precision industrial machinery.

The choice between a single-piece and a two-piece piston often boils down to a classic trade-off: ultimate durability versus long-term serviceability. For a "fit-and-forget" component inside a fully welded cylinder, the single-piece design is king. But for a tie-rod cylinder that’s designed for regular maintenance, a two-piece piston provides much-needed flexibility.

Specialised and Niche Piston Types

To help you decide, this table breaks down the most common piston designs and where they fit best.

Comparing Common Hydraulic Piston Designs

This table compares the primary types of hydraulic cylinder pistons, their typical applications, and key characteristics to guide your selection.

| Piston Type | Primary Application | Key Characteristic |

|---|---|---|

| Single-Piece Piston | Heavy-duty, high-shock load environments (e.g., excavators, industrial presses) | Maximum durability and strength; not designed for serviceability. |

| Two-Piece Piston | Industrial machinery, tie-rod cylinders requiring periodic maintenance. | Excellent serviceability; allows for seal and wear band replacement. |

| Annular Piston | Applications needing a through-rod or central passage (e.g., hollow cylinders). | Hollow centre for passing other components through. |

| Telescopic Piston | Multi-stage cylinders for long-stroke applications (e.g., tipper trucks, lifts). | A series of nested pistons that extend sequentially. |

While single and two-piece designs cover the vast majority of applications, it's worth knowing that the basic piston concept is adapted for more specialised jobs.

For instance, annular pistons are designed with a hollow centre, which allows another rod or component to pass right through them. You'll find these in specific setups where force needs to be applied around a central object.

Another key variation is found in telescopic cylinders. These use a series of nested pistons to achieve a very long stroke from a compact starting length, with each stage having its own piston that works in sequence. The components that drive these systems are fascinating in their own right; you can learn more about them in our guide to piston pumps.

Ultimately, matching the right piston design to the job ensures the hydraulic cylinder will perform reliably and efficiently, whether it's lifting tonnes of rubble on a building site or making micrometre-perfect movements in a cleanroom.

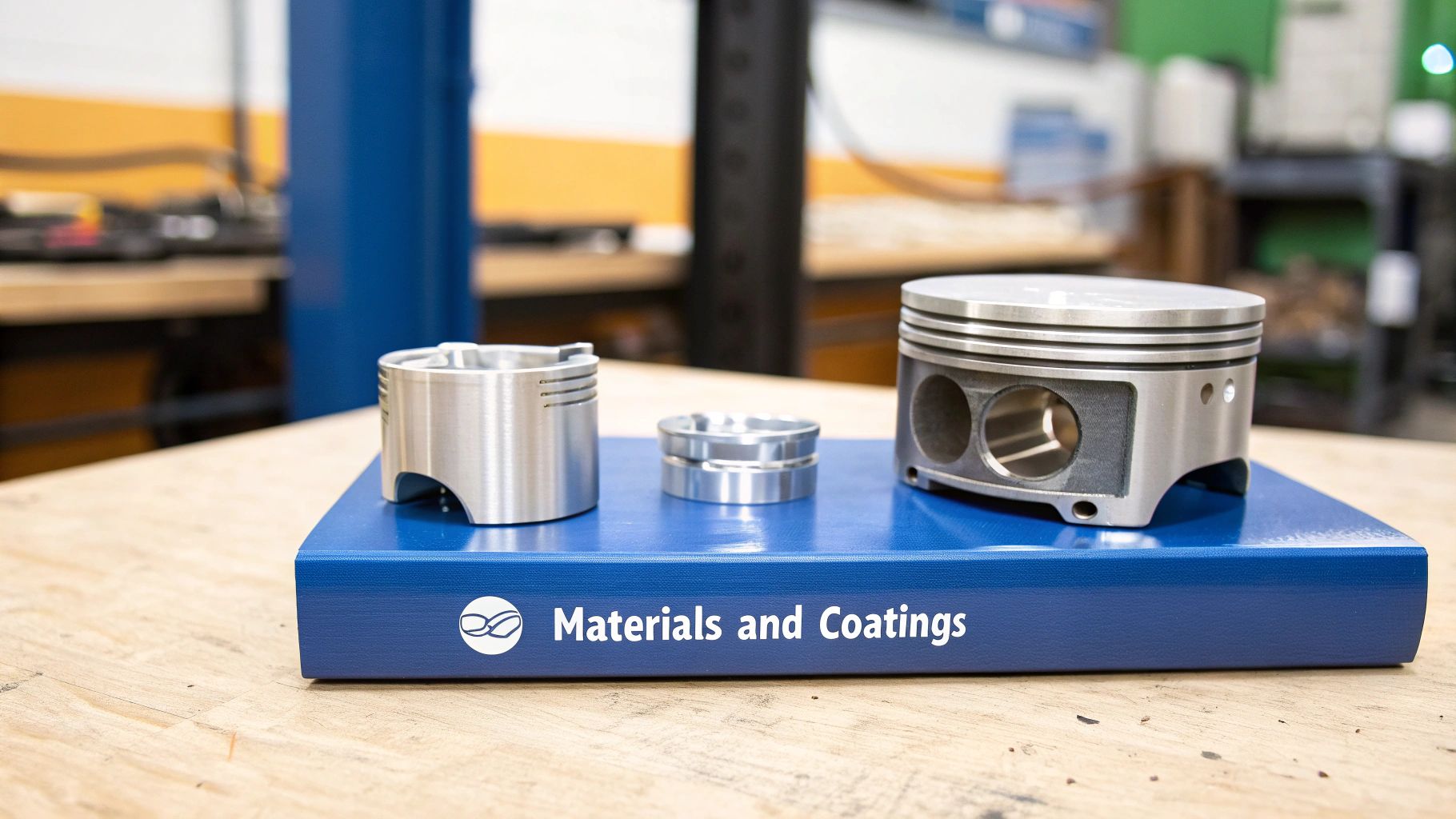

Choosing Piston Materials and Surface Coatings

The material you choose for a hydraulic cylinder piston has a huge impact on its strength, durability, and overall performance. Getting this right isn't a trivial detail; it’s a critical engineering decision. The piston needs to be able to withstand immense pressures and often brutal operating conditions without giving up.

At its core, the choice is a balancing act between strength, weight, and cost. Each material brings something different to the table, making it a better fit for some UK industries over others.

Core Materials for Piston Construction

When you’re dealing with high-pressure, heavy-duty applications, the material has to be incredibly tough. This is where high-tensile steels and ductile iron really shine.

- Ductile Iron: A very popular choice, and for good reason. It offers an excellent strength-to-weight ratio and great wear resistance. It's tough enough for the vast majority of industrial and mobile applications, making it a reliable and cost-effective workhorse.

- High-Tensile Steels (e.g., Carbon Steel): When the pressure really starts climbing, carbon steel is often the go-to material. Its superior strength and hardness make it perfect for the most demanding environments you can think of, from heavy construction plant to massive industrial presses.

But it’s not always about brute strength. In some hydraulic systems, weight becomes a much bigger factor, especially where speed and rapid cycling are the name of the game.

- Aluminium: We see this used in applications where cutting down on mass is the key to faster cycle times and better efficiency. It’s not as strong as steel, of course, but it’s ideal for lighter-duty or high-speed pneumatic and hydraulic systems.

- Bronze: You'll often find bronze used for bearings or wear bands on steel pistons. However, it can also be used for the entire piston body in certain jobs that need low friction or better corrosion resistance.

The material isn't just about handling pressure. It's about ensuring the piston's structural integrity over millions of cycles, resisting the kind of fatigue and deformation that could lead to catastrophic failure.

The Critical Role of Surface Coatings

While the piston's base material provides the muscle, the surface is where the real work happens. It’s the face that slides against the cylinder bore, and it needs to be incredibly hard, smooth, and resistant to both wear and corrosion. That’s where specialised surface coatings come in.

These treatments are far more than just a lick of paint; they fundamentally change the piston's surface to boost its performance and lifespan. Without them, the constant friction and chemical attack from the hydraulic fluid would chew up the piston in no time.

Some of the most common surface treatments include:

- Hard Chrome Plating: For decades, this has been the industry standard. A layer of hard chrome creates an exceptionally hard, low-friction surface that stands up brilliantly to wear and corrosion.

- Nitriding: This is a clever heat treatment process that diffuses nitrogen directly into the steel's surface, creating a case-hardened layer. Nitrided surfaces are extremely hard and offer fantastic resistance to scuffing and wear.

- Induction Hardening: This process uses an electromagnetic field to rapidly heat a specific area of the piston, which is then immediately quenched (cooled). This hardens the surface skin while leaving the core material tough and ductile enough to absorb shock loads.

Each of these coatings plays a vital part in cutting down friction. Less friction means less heat, and less heat means a more efficient cylinder.

Precision Tolerances and Surface Finish

The final piece of the performance puzzle is manufacturing precision. The tolerances on a hydraulic piston are incredibly tight – we're talking measurements in micrometres (µm). This mind-boggling accuracy is vital for one simple reason: to stop internal fluid bypass.

If the gap between the piston and the cylinder bore is too large, high-pressure fluid will sneak past the seals. This isn't just a small leak; it's a direct loss of power and efficiency. Every drop of fluid that bypasses the piston is energy that isn’t being turned into useful work.

Likewise, the surface finish is absolutely critical. A perfectly smooth surface (measured as a low Ra value) lets the seals create a tight barrier against the fluid, all while minimising friction and preventing the seals from wearing out. A rough or poorly finished surface will act like sandpaper, shredding the seals and leading to a fast failure. It’s this microscopic level of precision that makes a hydraulic cylinder perform at its best.

For help with sourcing or manufacturing a piston with the correct materials and tolerances for your system, phone us on 01724 279508 today, or send a message through our contact form.

Getting to Grips with Piston Seals and Groove Design

A hydraulic cylinder piston might look like a simple lump of metal, but its real power comes from something much smaller: the seals. Think of them as the unsung heroes of the entire system. These components are what stop high-pressure fluid from simply leaking past the piston head, a failure that directly translates into a costly loss of force.

Getting a handle on the relationship between the piston, its seals, and the grooves they sit in is absolutely essential for anyone looking to service or rebuild a hydraulic cylinder properly. The seal’s job is to form a dynamic, leak-proof barrier against the cylinder bore, holding back immense pressure while sliding back and forth. If that seal fails, you get internal slippage—the classic cause of slow, weak, or jerky cylinder movement.

Common Piston Seal Types and Materials

The world of piston seals is surprisingly varied. The design you need depends entirely on the job at hand—the pressures, speeds, temperatures, and even the type of hydraulic fluid being used.

- O-Rings: Often used to 'energise' other seals, but in very low-pressure or slow-moving jobs, they can sometimes act as the main seal themselves.

- U-Cups (or U-Seals): A hugely popular choice. Their 'U' shape cleverly uses the hydraulic pressure to push the sealing lips outwards, creating a tighter seal against both the piston groove and the cylinder wall as pressure increases.

- Composite Piston Seals: For high-performance systems, these are the go-to. They are usually a multi-part assembly, often featuring a tough, low-friction PTFE ring backed by a rubber O-ring. This combination gives you fantastic sealing efficiency and a much longer service life.

Just as important is the material. Nitrile (NBR) is a reliable workhorse for everyday applications. For high-temperature environments, you’ll likely need Viton™ (FKM). And when you need the best performance under high pressure with low friction, Polytetrafluoroethylene (PTFE) is often the top contender.

Why Piston Seal Grooves Are So Precisely Engineered

Those grooves machined into the piston aren't just arbitrary slots. They are precision-engineered features, and their dimensions are critical. The depth, width, and even the corner radii are carefully calculated to make the seal work exactly as it should.

A perfectly designed groove holds the seal securely but also gives it just enough room to be 'energised' by system pressure. This forces it against the cylinder bore to create a tight barrier without causing excessive friction or premature wear.

Get the groove dimensions wrong, and failure is just around the corner. Too deep, and the seal won’t make proper contact, causing a leak. Too shallow, and the seal gets crushed, leading to high friction, heat build-up, and rapid destruction. It’s a science. This precision is vital, especially when you consider the UK hydraulic cylinder market is projected to hit £1.05 billion by 2030. Welded cylinders, which dominate the market, often rely on pistons operating at up to 250 bar—a pressure that leaves no room for error. You can find out more on these trends in this full industry analysis.

The Role of Wear Bands

Look closely at a piston, and you’ll usually see other non-metallic rings alongside the seals. These are wear bands or guide rings. Made from durable, low-friction materials like bronze-filled PTFE or phenolic resin, their job isn't to seal fluid but to support the piston.

They are crucial for a few key reasons:

- They Prevent Scoring: They take the side-loads and stop the steel piston from grinding against the steel cylinder tube, which would cause catastrophic and expensive damage.

- They Maintain Alignment: By keeping the piston and rod perfectly centred, wear bands ensure the seals can do their job properly and last longer.

- They Extend Cylinder Life: Wear bands are sacrificial. They are designed to wear out over time, protecting the much more expensive piston and cylinder barrel from wear and tear.

It's this teamwork between the seals, the wear bands, and the precision-machined grooves that allows a hydraulic cylinder to deliver its power reliably and efficiently.

For expert advice on sourcing the right seals and pistons for your equipment, give us a call on 01724 279508 or send us a message online.

Diagnosing Common Piston Failure Modes

When a hydraulic cylinder starts acting up—losing power, drifting under load, or moving erratically—the piston is often where the trouble lies. To a trained eye, a failed piston tells a story. Learning to read the signs of wear and damage is a vital skill for any maintenance team, as it helps you move beyond just swapping a part and start tackling the root cause of the problem. This is how you prevent the same failure from happening all over again.

Scoring and Deep Scratches

Scoring is one of the most common—and destructive—ways a piston can fail. It shows up as long scratches or deep grooves running along the piston's surface, and if it’s bad enough, you’ll see matching damage on the cylinder bore itself. These marks are almost always a tell-tale sign of contamination in the hydraulic fluid.

What happens is that hard particles, like tiny metal shavings from another worn-out component or just plain old dirt, get into the system. They become trapped between the piston seals and the cylinder wall, and as the piston strokes back and forth, they’re dragged along, gouging both surfaces.

Scoring is a massive red flag. It’s telling you that your system's filtration is either inadequate or has been seriously compromised. If you just replace the piston without flushing the system and checking the filters, you're setting yourself up for a repeat failure in no time.

To stop this from happening, you need to:

- Check the fluid: Look for any visible grit or send a sample off for a proper analysis.

- Inspect your filters: Make sure they're the right micron rating and aren't stuck in bypass mode.

- Look for entry points: Check for worn-out rod wipers or damaged breather caps where dirt could be getting in.

Deformed or Extruded Piston Seals

If you pull a cylinder apart and find the piston seals look flattened, have chewed-up edges, or seem to be squeezed into the gaps, you're looking at seal extrusion. This is classic evidence of either over-pressurisation or excessive clearances.

Seals are engineered to handle a specific amount of pressure and work within tight clearance gaps between the piston and the cylinder bore. If the system suffers a pressure spike way beyond its design limits, the seal material gets physically forced into any available space. This shears off little pieces of the seal, causing it to fail and leak internally almost instantly.

The same thing can happen if the wear bands are worn down. As they wear, the gap between the piston and the bore widens, allowing even normal operating pressures to extrude the seal. The result is an internal leak, which leads to a loss of holding force and that frustrating cylinder drift.

Burned or Hardened Seals

A piston seal that feels brittle, is covered in cracks, or has a glazed, burnt look is shouting one thing: excessive heat. Hydraulic systems are designed to operate within a set temperature range, typically staying below 82°C (180°F).

Once temperatures climb above this, common seal materials like Nitrile (NBR) start to cook. They become hard and lose their flexibility, which means they can no longer form a proper seal against the cylinder bore, leading to fluid bypass. This high heat usually comes from one of a few places:

- Hot working conditions: Operating machinery in a very warm environment without enough cooling.

- System inefficiency: A worn pump or other internal leaks can generate a surprising amount of heat.

- Blocked flow: A clogged oil cooler or a valve that’s not fully open can cause fluid temperatures to skyrocket.

By correctly identifying the specific failure mode—be it scratches, deformed seals, or heat damage—you’ve taken the first and most important step towards a lasting repair. You're no longer just treating the symptom; you're diagnosing the real system-level problem.

For expert help in diagnosing piston failures or to source high-quality replacement components, our technical team is here to help. Give us a call on 01724 279508, or send us a message to get your hydraulic systems back to peak condition.

Your Partner for Hydraulic Piston Solutions

Getting to grips with the finer points of a hydraulic cylinder piston—its design, materials, seals, and how it can fail—is one thing. But the real challenge? Finding the right component to keep your machinery running at its absolute best. This is where theory meets reality, and where deep technical knowledge needs to turn into a practical, reliable part in your hand.

At MA Hydraulics, we live and breathe this stuff. We're specialists in bridging that gap between knowing what you need and actually getting it. Think of us less as just a supplier, and more as your technical partner in all things hydraulics.

Sourcing and Supplying the Right Piston

Whether you have a straightforward replacement job or a tricky, one-off requirement, we’ve built the resources and network to help. We’ve seen it all, and our services are set up to get you the exact component you need with minimal fuss and downtime.

Here’s how we can help:

- Sourcing Specific Parts: We can supply pistons from top-tier, reliable brands like Vivoil, making sure you get a component that meets or exceeds OEM standards.

- Cross-Referencing Obsolete Components: Struggling with an older, discontinued cylinder? Our team has the know-how to dig into old part numbers and find a modern, perfectly suitable replacement.

- Manufacturing Bespoke Pistons: For custom machinery or highly specialised applications, we can arrange for bespoke pistons to be designed and machined precisely to your specifications.

Technical Expertise You Can Count On

Picking the right piston is about so much more than just matching a few dimensions. It demands a proper understanding of pressure ratings, material compatibility, seal arrangements, and the specific stresses of the job it has to do. For example, choose the wrong seal material, and you could be looking at premature failure in a high-temperature environment. Specify the piston incorrectly, and you might face inefficient performance or, worse, catastrophic damage.

Our technical team is here to provide that crucial application advice to stop these problems before they start. We make sure every hydraulic cylinder piston we supply is a perfect match for its role, ensuring you get maximum efficiency, reliability, and service life from your systems.

Whether you're carrying out routine maintenance or in the middle of a full-scale system overhaul, having a partner you can trust is essential. While the piston is the heart of the cylinder, we know that other components like hydraulic hand pumps are just as vital in many setups. It’s all connected. Our job is to give you both the components and the confidence to keep your operation running smoothly.

For expert advice or to source your next hydraulic component, give us a call on 01724 279508 today, or send us a message via our website contact form at https://www.mahydraulics.co.uk/contact-us/.

Got Questions About Hydraulic Pistons? We've Got Answers.

When you're trying to diagnose a cylinder fault or specify a new component, getting to the bottom of how a hydraulic cylinder piston works is crucial. Here are some of the most common questions our team of engineers and technicians field every day here in the UK.

What’s the Piston's Real Job in a Hydraulic Cylinder?

Think of the piston as the engine of the cylinder. Its most basic role is to act as a barrier, separating the two pressure chambers inside the cylinder barrel.

But its true purpose is converting the hydraulic fluid's pressure into raw mechanical power. When high-pressure fluid pushes against one side of the piston, it forces the attached rod to move, delivering the linear force needed to lift a skip, crush a car, or steer a tractor. It’s where the magic really happens.

How Can I Tell if a Hydraulic Piston Is on Its Way Out?

The classic symptom is a loss of power or drift, something we call 'piston bypass'. This is where fluid starts to leak past worn-out piston seals from the high-pressure side to the low-pressure side. You'll notice the cylinder acting slow, weak, or jerky under load.

Another tell-tale sign is an external leak from the rod seal. That internal bypass builds up pressure where it shouldn't be, eventually overwhelming the rod seal and causing a visible leak. If you get the cylinder apart, look for scoring on the piston itself, or seals that are hard, brittle, or look like they've been chewed up.

Should I Just Replace the Seals or the Whole Piston?

That really depends on what you find when you strip the cylinder down. If the piston body itself is in great shape—no deep scratches, cracks, or damage to the seal grooves—then a new set of seals is usually a perfectly good, cost-effective repair.

However, if that piston is scored, cracked, or the grooves are worn, just changing the seals is a temporary fix that's doomed to fail. New seals won't last long on a damaged surface. In that situation, replacing the entire piston is the only way to guarantee a reliable, long-term repair.

For expert support with all your hydraulic cylinder piston requirements—from identifying the right part to bespoke manufacturing—MA Hydraulics has you covered. Phone 01724 279508 today, or send us a message to get started.