A quick release coupler hydraulic system is essentially a high-strength, instant connector for your fluid power lines. Think of it like a garden hose connector, but engineered to handle immense pressures safely and reliably. It lets you attach and detach hydraulic tools and hoses in seconds, all without needing a single tool. This ability to make rapid changes is what makes modern machinery so incredibly versatile.

What Are Quick Release Hydraulic Couplers?

Picture this: you need to change a heavy excavator bucket, but first, you have to manually unbolt the hydraulic hoses. It would be a slow, messy, and potentially dangerous job, leading to a lot of wasted time. The quick release hydraulic coupler eliminates this problem entirely. It’s a specialised fitting that creates a secure, leak-free seal between two hydraulic lines with a simple push-and-click or screw-on motion.

This simple but crucial component is a cornerstone of modern hydraulic systems. It’s made of two halves—a male plug (or nipple) and a female socket (or coupler)—that lock together firmly. Inside, clever valving in both halves automatically shuts off the flow of hydraulic fluid the moment they're disconnected. This masterstroke of engineering prevents messy spills and stops air or contaminants from getting into the system.

The Core Benefits for UK Industries

In fast-moving sectors like agriculture, construction, and manufacturing, efficiency is everything. Every minute a machine is out of action translates directly to lost productivity and higher running costs. This is where the true value of a quality quick release coupler really shines.

- Boosted Productivity: Operators can switch between different attachments—like grapples, breakers, or shears—in a matter of minutes, not hours. A farmer can quickly swap implements on a tractor, or a construction worker can adapt an excavator for various tasks right there on site.

- Improved Safety: The design itself minimises hydraulic fluid spillage, which is a major slip hazard and an environmental headache. It also cuts down the risk of high-pressure fluid injection injuries that can happen when manually handling hoses.

- Guarding System Integrity: Keeping contamination out is absolutely vital for the lifespan of any hydraulic system. A well-made coupler creates a clean break, stopping dirt, dust, and moisture from sneaking into the sensitive inner workings of your pumps and valves.

By making connections so straightforward, the quick release coupler hydraulic fitting turns a single-purpose machine into a multi-functional workhorse. This adaptability is non-negotiable for any business wanting to get the best possible return on its expensive equipment. When you browse the range of hydraulic accessories, you’ll notice how these couplers are the foundation for flexible and efficient operations.

Getting to Grips with the Main Types of Hydraulic Couplers

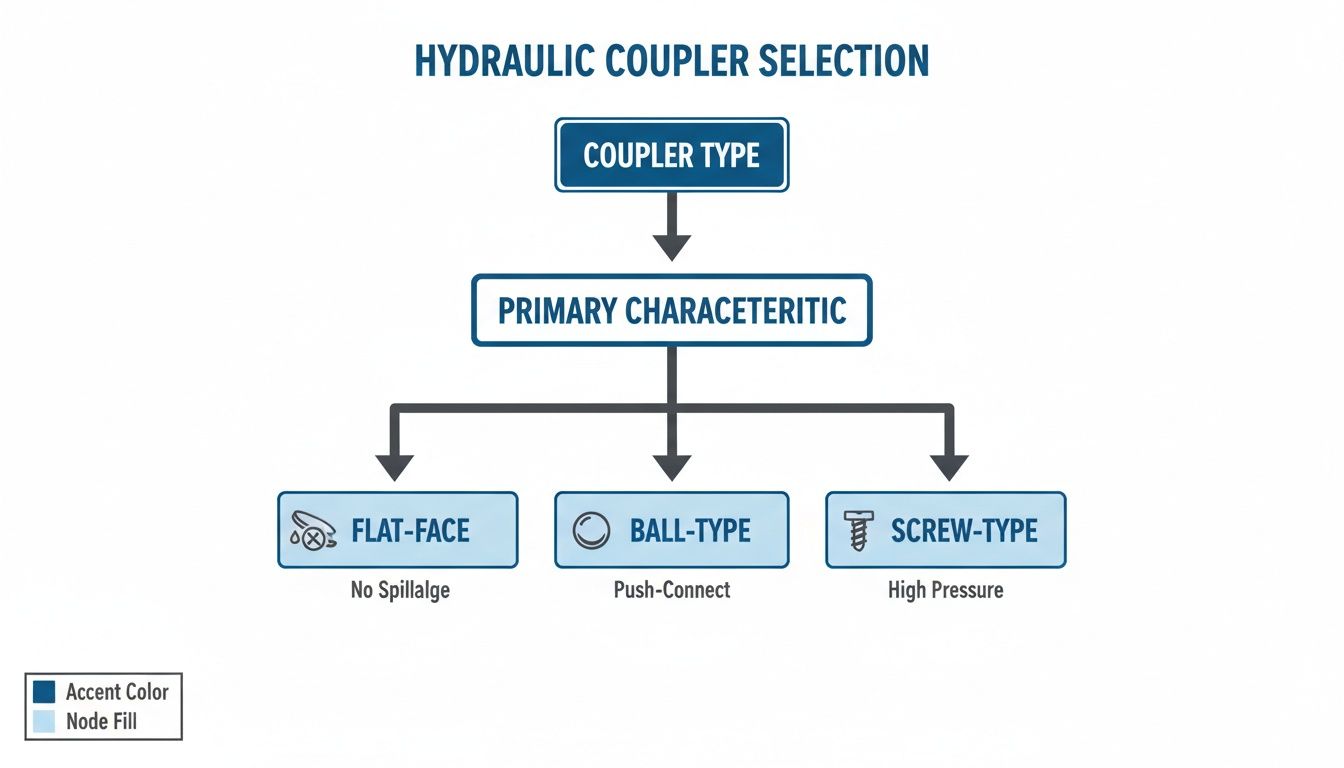

When you're dealing with hydraulic quick-release couplers, it’s important to know that they aren't all created equal. The design of a coupler is what dictates its performance, how safe it is, and whether it’s the right tool for the job. In the UK, you’ll mainly come across three types: Flat-Face, Ball-Type, and Screw-to-Connect.

Choosing the right one isn't just a matter of preference; it's a decision that directly affects your efficiency, your environmental footprint, and the lifespan of your equipment. Get it wrong, and you could be looking at leaks, pressure loss, or connection failures—all of which lead to expensive downtime and serious safety risks.

Flat-Face Couplers: The Clean, Modern Standard

For most modern hydraulic systems, flat-face couplers are the go-to choice, and for good reason. Often built to the ISO 16028 standard, their design is brilliantly simple. When you disconnect them, the two surfaces are perfectly flat, making them incredibly easy to wipe clean. This is a massive advantage when it comes to keeping contaminants out of your system.

Their biggest selling point is the near-zero spillage. When you pull them apart, you lose barely a drop of fluid. This makes them perfect for working in environmentally sensitive locations or indoors where a clean workspace is non-negotiable. This design also prevents air from getting sucked into the system on connection, protecting vital components like pumps and valves from the damage cavitation can cause.

Think about this: a single litre of hydraulic oil can contaminate up to one million litres of water. Suddenly, the "no-drip" feature of a flat-face coupler isn't just a nice-to-have, it's an essential part of responsible operation.

Ball-Type Couplers: The Tried-and-Tested Workhorse

Ball-type couplers, which you might also hear called poppet-style, are a more traditional design. They rely on a ball-bearing locking system and a poppet valve to start and stop the flow of fluid. For decades, they've been a reliable staple on farms and in older industrial machinery, but they do have their limitations compared to the newer flat-face designs.

The main drawback is the spillage. You're almost guaranteed to lose some fluid when connecting or disconnecting. The recessed poppet valve is also a magnet for dirt, which can easily get pushed into the hydraulic system. That said, they are often cheaper and can be a perfectly fine choice for applications where a small amount of fluid loss isn't a major issue. You'll still see them all over older tractors and general-purpose hydraulic tools.

Screw-to-Connect Couplers: For When the Pressure Is On

When you’re dealing with extremely high pressures or the kind of intense pressure spikes you get with heavy machinery, screw-to-connect couplers are the undisputed champions. Instead of a simple push-to-connect sleeve, these have a threaded mechanism you tighten by hand. This creates a rock-solid, vibration-proof connection that can handle the toughest conditions.

You'll find them on heavy-duty kit like demolition equipment, rock breakers, and massive hydraulic presses. The threaded connection guarantees the coupler won't pop off under severe vibration or a sudden pressure surge. They are also brilliant for connecting lines that have residual pressure trapped inside, which often happens when fluid expands due to heat. For demanding power transmission, exploring options like the OMT ND500 series couplings can provide the ruggedness you need.

To help you decide, here’s a quick breakdown of how these different types stack up against each other.

Comparison of Hydraulic Coupler Types

| Coupler Type | Key Feature | Best For | Spillage Level | Pressure Rating |

|---|---|---|---|---|

| Flat-Face | Easy to clean, minimal spillage | Environments where cleanliness is critical; modern machinery | Very Low | Medium to High |

| Ball-Type | Economical, widely available | Older equipment, general-purpose applications | Medium | Low to Medium |

| Screw-to-Connect | Extremely secure threaded connection | High-pressure, high-vibration, and impulse applications | Low | Very High |

This table gives you a general guide, but the best choice always comes down to the specifics of your application.

The impact of choosing the right technology is clear. Across the UK's agriculture and construction industries, switching to modern couplers has made a huge difference. For example, one large-scale refurbishment project found that replacing old couplings with no-spill, flat-face types on heavy machinery led to a 28% drop in fluid leakage incidents.

Considering hydraulic oil can cost £15-£20 per litre and Environment Agency fines for spills are steep, that's a significant saving. The same project also saw connection times fall from five minutes to under 30 seconds, boosting productivity by up to 20% in busy seasons—a massive gain in industries where every minute of downtime counts.

How to Select the Right Quick Release Coupler

Choosing the right quick-release coupler isn’t just about finding something that fits. It's a decision that has a direct impact on your system’s performance, its safety, and how long it will last. Get it right, and you’ll avoid costly failures, frustrating leaks, and a lot of unnecessary downtime.

This guide will walk you through the essential factors, making sure you specify a coupler that’s a perfect match for what your application demands.

To get this right, you need to analyse four key operational parameters. Think of these as the non-negotiables that dictate which coupler will succeed and which will fail under pressure. Nail these from the start, and you'll save yourself a tremendous amount of time, money, and stress down the line.

Analysing Your System's Demands

Before you can even think about picking a coupler, you need a crystal-clear picture of the environment it will be working in. The main things to look at are pressure, flow rate, fluid type, and operating temperature. Each one plays a critical role.

Operating Pressure: What's the maximum working pressure of your hydraulic system? Always choose a coupler with a pressure rating that comfortably exceeds your system’s maximum, measured in bar. This gives you a vital safety margin, especially in applications known for pressure spikes, like hydraulic hammers or heavy presses.

Flow Rate: How much fluid needs to get through the coupler, measured in litres per minute (LPM)? The coupler's internal diameter has to be big enough to handle this flow without causing a significant pressure drop. A restrictive coupler acts like a bottleneck, making the pump work harder, which just generates excess heat and wastes energy.

Fluid Compatibility: What kind of hydraulic fluid are you running? Most systems use standard mineral oils, but yours might use water-glycol, phosphate esters, or other specialised fluids. The coupler’s body material and, just as importantly, its internal seals must be compatible with the fluid to stop them from degrading, swelling, or leaking.

Operating Temperature: You need to consider both the ambient temperature of the work environment and the temperature of the fluid itself. Extreme heat or cold can seriously affect how well the seals perform. Standard Nitrile (NBR) seals are fine for a wide range of jobs, but Viton (FKM) seals are a much better bet for higher temperatures or when dealing with more aggressive fluids.

This decision tree gives you a great visual starting point for the selection process.

As you can see, the specific needs of your application, like preventing spills or handling high pressure, point you directly towards a particular type of coupler.

The Importance of Material and ISO Standards

Beyond the basic operating specs, the actual physical construction of the coupler is paramount. Your choice of material and whether it sticks to international standards is what separates a reliable component from a potential point of failure.

For most agricultural and construction machinery, high-strength carbon steel is the go-to choice. It gives you excellent durability and pressure resistance without breaking the bank. However, if you’re working in a corrosive environment—think marine applications, food processing, or chemical plants—stainless steel is essential to prevent rust and ensure the part lasts.

ISO (International Organization for Standardization) standards are your guarantee of interchangeability. An ISO 16028 flat-face coupler from one brand will connect perfectly with an ISO 16028 coupler from another. This is absolutely crucial if you're managing a mixed fleet of equipment or trying to source spares.

Sticking to standards like ISO 7241-A/B for ball-type couplers or ISO 16028 for flat-face couplers ensures you’re not locked into a single supplier. It gives you flexibility and the confidence that your connections are reliable and meet industry-recognised performance benchmarks.

Matching the Coupler to the Application

Let's put this into practice with a couple of real-world UK scenarios.

Scenario 1: Construction Excavator Attachments: A 20-tonne excavator needs to switch between a digging bucket and a hydraulic breaker. The system runs at 280 bar with a flow rate of 150 LPM. On a busy site, the priority is fast, clean changeovers. The clear winner here is a Flat-Face (ISO 16028) coupler. Its no-spill design prevents contamination and oil spills, and its robust construction handles the high pressure with ease.

Scenario 2: Industrial Power Pack in a Factory: An indoor hydraulic power pack is running a press. The system pressure is a steady 210 bar, but it’s prone to high-pressure spikes. Fluid cleanliness is important, but the number one concern is a connection that won’t vibrate loose. A Screw-to-Connect coupler is the superior option here. Its threaded design offers maximum security against both pressure impulses and vibration. For these kinds of system builds, using properly matched components like port adaptors ensures every single part of the circuit is up to the job.

By carefully working through these factors—pressure, flow, fluid, materials, and standards—you can confidently pick the right quick release coupler that guarantees safety, efficiency, and reliability for your machinery.

Installation and Maintenance Best Practices

Let's be blunt: even the best quick-release coupler in the world is only as good as its installation and upkeep. You can have the highest-spec fitting, but if it's not handled correctly from day one, you're setting yourself up for failure. Getting these fundamentals right isn't just about best practice; it's the single most effective way to guarantee a long, leak-free service life and keep your machinery running exactly as it should.

Think of it as preventative medicine for your hydraulic system. A few simple steps at the start and a bit of routine care can prevent the vast majority of common issues that lead to costly downtime, performance loss, and serious safety risks.

Pre-Installation Checks: The Essential First Steps

Before you even think about connecting that new coupler, take a breath. Rushing this stage is where so many problems begin, often leading to immediate leaks or damage. Remember, contamination is the number one enemy of any hydraulic circuit, and this is its prime opportunity to sneak in.

Run through this quick checklist every single time:

- Kill the Pressure: This is non-negotiable. Crucially, ensure the hydraulic system is completely de-pressurised. Trying to connect or disconnect under pressure is incredibly dangerous, risking a high-pressure oil injection injury or catastrophic failure of the coupler itself. Always follow the machine manufacturer's procedure for safely dumping the pressure.

- Cleanliness is Everything: Get a clean, lint-free cloth and thoroughly wipe both the male plug and the female coupler. Pay close attention to the threads and the sealing faces. A single grain of sand or bit of grit can permanently damage a seal and prevent a proper connection.

- Inspect Your Parts: Give the new coupler a quick once-over. Are the threads clean and free of dings? Are the O-rings and seals seated properly, with no nicks or cuts from shipping? A 10-second check now can save hours of frustration later.

The Right Way to Connect and Disconnect

Connecting a quick-release coupler might seem simple, but doing it correctly prevents a lot of unnecessary wear and tear. For most standard push-to-connect types, all it takes is a firm, straight push. You're listening for that satisfying 'click' that tells you the locking mechanism has fully engaged.

When it's time to disconnect, retract the sleeve on the female half and pull the male plug straight out. Resist the urge to wiggle it or pull the hoses at an angle. That puts sideways stress on the coupler, which over time will wear out the internal valves and locking balls.

One of the worst things we see is someone using a hammer to force a connection. If a coupler won’t connect smoothly, the cause is almost always trapped pressure or dirt. Forcing it will only destroy the components, turning a simple problem into a very expensive repair.

A Simple Maintenance Schedule for Longevity

When it comes to hydraulics, proactive care always beats reactive repairs. By giving your couplers a regular look, you can spot the early signs of trouble and sort them out before they become big, expensive problems. You don't need a complicated schedule; a few simple habits will dramatically extend the life of your fittings.

Daily/Pre-Use Checks:

- Quick Visual: Before you start the day's work, just glance at the couplers. Look for any obvious damage, bad corrosion, or drips.

- Wipe Down: If you’re on a dusty construction site or a muddy farm, give the couplers a quick wipe. A set of protective dust caps is a tiny investment that pays for itself a hundred times over by keeping dirt out.

Periodic Inspections (e.g., Monthly):

- Leak Watch: Check the connection point for any sign of weeping hydraulic fluid. A slightly damp fitting is often the first warning that an internal seal is on its way out.

- Check for Wear: Look for deep scratches or dents on the male plug or heavy wear on the locking sleeve. Any damage to these surfaces can compromise the seal.

- Function Check: Does it still connect and disconnect smoothly? If it’s getting stiff or gritty, that’s a sure sign of internal contamination or wear in the locking mechanism.

By building these simple installation and maintenance steps into your routine, you’ll ensure your quick release coupler hydraulic system stays reliable, efficient, and safe for its entire working life.

Getting to Grips with Common Coupler Problems

Even the most reliable quick-release hydraulic coupler has a bad day. When a connection seizes up, starts weeping fluid, or just refuses to cooperate, it can grind your whole operation to a halt. The good news? Most of the time, the culprit is something simple and easy to spot.

If you know what you’re looking for, you can get things moving again with minimal fuss and downtime. Let's walk through the most common headaches you’ll face and how to sort them out.

Why Won't It Connect?

This is probably the most frustrating issue of all. You're pushing, you're leaning on it, but the coupler just won't click home. Nine times out of ten, the coupler itself isn't faulty—it's just a symptom of a problem elsewhere in the hydraulic circuit.

The number one cause is trapped pressure. Leave an attachment hose lying in the sun, and the fluid inside will expand. This tiny bit of pressure creates a powerful hydraulic lock, making it physically impossible for you to push against it and open the internal valves.

- The Cause: Hydraulic fluid expanding due to heat, or pressure not being fully dumped from the circuit before you tried to disconnect.

- The Fix: You need to relieve that pressure safely. Every machine has a specific procedure for this, so check the manufacturer’s guide. Never, ever crack open a fitting to "bleed" the line. A high-pressure jet of hydraulic oil can cause a devastating injection injury. While specialised connect-under-pressure couplers exist, they aren't standard kit.

The other common reason is far simpler: dirt. A bit of grit, a woodchip, or some caked-on mud in the female half is all it takes to physically block the male probe. A quick wipe of both ends before you connect is a habit that pays off.

What to Do About Weeps and Leaks

A leaking coupler is more than just an oily mess. It's a safety hazard, an environmental risk, and a clear signal that something is wrong. That tiny drip can quickly become a serious leak, costing you a fortune in hydraulic fluid and risking system failure.

The most likely suspect is a damaged or worn seal. The O-rings and backup rings are your first line of defence, but they're easily compromised.

- Contamination: Dragging a male probe coated in dirt across the seal is a surefire way to slice or nick it.

- Wrong Fluid: Using a hydraulic oil that’s incompatible with the seal material (like putting aggressive synthetic oil in a system with standard NBR seals) will cause them to swell, harden, and eventually fail.

- High Temperatures: Running too hot makes seals brittle. They lose their flexibility and can no longer create an effective seal.

That slow, steady drip from the connection point is the classic tell-tale sign of a failing internal seal. Don't ignore it. A new seal kit is cheap and quick to fit. A new coupler, damaged from a long-term leak, is a much bigger bill.

When Couplers Wear Out Too Fast

If you seem to be replacing couplers far more often than you should, it's time to play detective. Premature failure usually means your operating conditions are pushing the component past its limits.

The main culprits that accelerate wear and tear are:

- Excessive Side-Loading: Pulling on hoses at a sharp angle puts a huge strain on the locking mechanism and internal parts, causing them to wear unevenly.

- High-Frequency Pressure Spikes: Systems with things like hydraulic hammers create brutal, rapid-fire pressure impulses. A standard coupler just isn't built for that kind of punishment and will eventually fail from fatigue. A heavy-duty screw-to-connect type is a much better choice for these jobs.

- Constant Vibration: Heavy, non-stop vibration can wear down the locking balls and sleeves, leading to a loose connection that leaks or fails without warning.

A proactive approach to troubleshooting is essential. On a large UK construction site, downtime can easily cost upwards of £2,500 per hour. In an industry valued at over £120 billion, every minute counts. Given that quick-release systems can slash attachment changeover times by 40%, keeping these crucial components healthy is a no-brainer. You can read more about the trends in the global hydraulic couplings market on dataintelo.com. By correctly identifying and fixing these common issues, you’ll extend the life of your quick release coupler hydraulic components and keep your systems running smoothly.

Finding the Right Hydraulic Partner

Getting the right quick release coupler hydraulic part isn't just about ticking boxes. It's about ensuring your machinery runs safely, efficiently, and without costly interruptions. As we've covered, understanding the different types, matching the specs to your job, and keeping up with proper maintenance are all key to getting the most out of your equipment. Now, it's time to put that knowledge to work with a partner who really gets it.

At MA Hydraulics Ltd, we don’t just sell parts; we provide solutions. We keep a massive stock of top-quality brands on the shelf and have the hands-on expertise to match the right component to your exact needs, even cross-referencing old or obscure parts. Our team knows that what works for a heavy-duty excavator won't be right for a sensitive industrial press – every application has its own unique challenges.

Whether you're after a single replacement coupler to get you out of a jam or need a complete, bespoke power pack designed from scratch, we’re here to help. Our goal is simple: get you the right part, first time, every time. That means less downtime for you and better performance from your machinery. Don't leave something as critical as your hydraulic system to guesswork.

Frequently Asked Questions

When it comes to the day-to-day use of hydraulic quick-release couplers, a few questions pop up time and time again. Getting the right answers is crucial for keeping your machinery running safely and efficiently. Here, we tackle some of the most common queries we hear from engineers, operators, and maintenance teams across the UK.

Can I Connect a Coupler While the System Is Under Pressure?

In a word: no. You should never try to connect or disconnect a standard hydraulic coupler while the system is pressurised. Not only is it incredibly difficult because of the trapped fluid, but it’s also extremely dangerous. A sudden release of high-pressure fluid can cause severe injection injuries—a serious medical emergency—and you’ll almost certainly damage the coupler's internal valves and seals in the process.

Always follow the proper procedure to de-pressurise the system first. There are special 'connect-under-pressure' couplers designed for specific situations, like when thermal expansion traps fluid in a hose, but these are the exception, not the rule.

Are Quick-Release Couplers from Different Brands Interchangeable?

This is a big one for anyone running a mixed fleet of equipment. The answer is yes, but with a major caveat: only if they conform to the same ISO standard. For example, an ISO 16028 flat-face coupler from one manufacturer should connect seamlessly with an ISO 16028 coupler from another.

The danger comes when you try to mix brands that don't share a recognised standard. That’s a recipe for a poor connection that leaks, restricts flow, or fails completely under load. Before you ever connect two different halves, double-check that they are built to the same ISO standard.

A mismatched connection isn't just an annoyance; it’s a ticking time bomb. Taking a moment to verify interchangeability protects your equipment, prevents expensive fluid loss, and keeps your operators safe. If you have any doubt, stick with the same brand or get an expert opinion.

Why Is My New Flat-Face Coupler Weeping Fluid?

It's unsettling to see a slight weep of oil around a brand-new flat-face coupler, but don't panic. The cause is usually straightforward. More often than not, it's a tiny piece of dirt or debris trapped between the mating surfaces, preventing that perfect, metal-to-metal seal.

The first port of call is to disconnect the coupler and give both the male and female faces a thorough wipe with a clean, lint-free cloth. Reconnecting them should solve the problem. If the weeping continues after a good clean, it might mean a seal got nicked or damaged during installation. In that case, you'll need a new seal to sort it out.

For expert advice on any hydraulic component or to troubleshoot a specific issue with your quick release coupler hydraulic system, the team at MA Hydraulics Ltd is ready to help. Phone 01724 279508 today, or send us a message.