Picture this: you’re out in a remote field, miles from the nearest power socket, and you need to lift several tonnes. Or maybe a power cut has brought your workshop to a standstill. This is exactly where the hydraulic hand pump proves its worth.

Put simply, it’s a mechanical device that takes your manual effort—pumping a handle up and down—and transforms it into incredible hydraulic force.

What Are Hydraulic Hand Pumps and Why Do They Matter?

A hydraulic hand pump works on a beautifully straightforward principle, not unlike the car jack in your boot. A few easy pumps of a lever, and you can lift a vehicle weighing well over a tonne.

The real genius of a hand pump is its total independence. It needs no electricity, no engine, and no external power source whatsoever. This makes it an unbelievably reliable tool for emergency backups, delicate control tasks, or any equipment that operates off-grid.

From agricultural machinery in the fields of Lincolnshire to critical marine systems off the coast, these pumps are the unsung heroes of UK industry. They ensure that essential functions can always be carried out, no matter what. Their simple design hides a surprising amount of power and importance across countless industrial and mobile applications.

The Core Purpose of a Hand Pump

At its heart, a hand pump is a force multiplier. It gives a single person the ability to generate enormous pressures, often hitting over 700 bar (or 10,000 psi), with just a manageable amount of physical effort. This is crucial in situations where other power sources just aren’t an option—either because they’ve failed, aren’t available, or are simply impractical.

Hydraulic hand pumps play a few key roles:

- Primary Power Source: For equipment like workshop presses, log splitters, or certain tools where a fully powered system would be overkill or too expensive. A hand pump for a small press, costing somewhere between £150-£300, can provide serious force without needing complex electrical or engine hook-ups.

- Emergency Backup: Many larger systems have a hand pump built-in as a manual override. If the main powered unit on a piece of mobile plant gives out, the operator can use the hand pump to safely lower an attachment or retract a cylinder.

- Precise Control: When you need slow, careful, and deliberate movement—like tensioning large bolts or gently positioning heavy components—a hand pump gives you far better control than a powerful, fast-moving powered system.

- System Testing: Engineers and technicians often rely on hand pumps to pressurise hydraulic circuits. It’s the perfect way to check for leaks and test functionality before connecting the main power source and commissioning the system.

A hydraulic hand pump provides reliability when it matters most. Its ability to function without external power makes it an essential safety and operational tool, ensuring that you always have a way to control your hydraulic system, no matter the circumstances.

This guide will get into the nitty-gritty of how these seemingly simple devices are so vital for both original system design and day-to-day maintenance. Once you understand how they work and where they fit in, you can make much better decisions about using them in your own equipment.

To get a feel for the different technologies available, it’s worth exploring our wider range of hydraulic pumps.

Whether you’re designing brand-new equipment or keeping existing machinery running, the humble hydraulic hand pump remains a cornerstone of fluid power—a dependable solution that’s always ready when you need it most.

Understanding How a Hand Pump Creates Force

So, how does a simple back-and-forth movement of a handle generate enough power to lift several tonnes of machinery? The magic isn’t in brute strength but in a fundamental law of physics: Pascal’s Law.

In simple terms, Pascal’s Law states that when you apply pressure to a fluid in a sealed container, that pressure is transmitted equally, in all directions, throughout the entire fluid.

A hydraulic hand pump is a masterclass in exploiting this principle to multiply force. When you move the handle, you’re pushing a small piston that applies a bit of force to the hydraulic oil inside the pump.

Because the oil is trapped within the system’s hoses and components, that pressure has to go somewhere. It travels instantly through the entire hydraulic circuit and pushes against a much larger piston, usually inside a hydraulic cylinder. This difference in piston size is what multiplies your initial effort, turning a small push into a massive output force. It’s a perfect example of mechanical advantage.

Tracing the Fluid’s Journey

To really get your head around how pressure builds with each stroke, it helps to follow the oil’s path. The whole process is a beautifully simple, controlled sequence designed to push oil in one direction only.

- Reservoir to Pump: On the intake stroke (when you pull the handle up), the small piston creates a vacuum. This sucks hydraulic oil from the reservoir into the pumping chamber.

- The Role of Check Valves: A one-way check valve opens to let the oil in but slams shut to stop it from flowing back to the tank. Think of these valves as the system’s bouncers, only letting traffic flow one way.

- Building Pressure: On the power stroke (when you push the handle down), the piston forces this trapped oil out of the chamber. The suction check valve is now closed, but another check valve on the outlet side opens, letting the high-pressure fluid head towards the cylinder.

- Repeat for More Power: Every pump of the handle repeats this process, sending another “shot” of pressurised fluid into the system. It’s a bit like using a bicycle pump—each stroke adds more air, steadily increasing the pressure in the tyre.

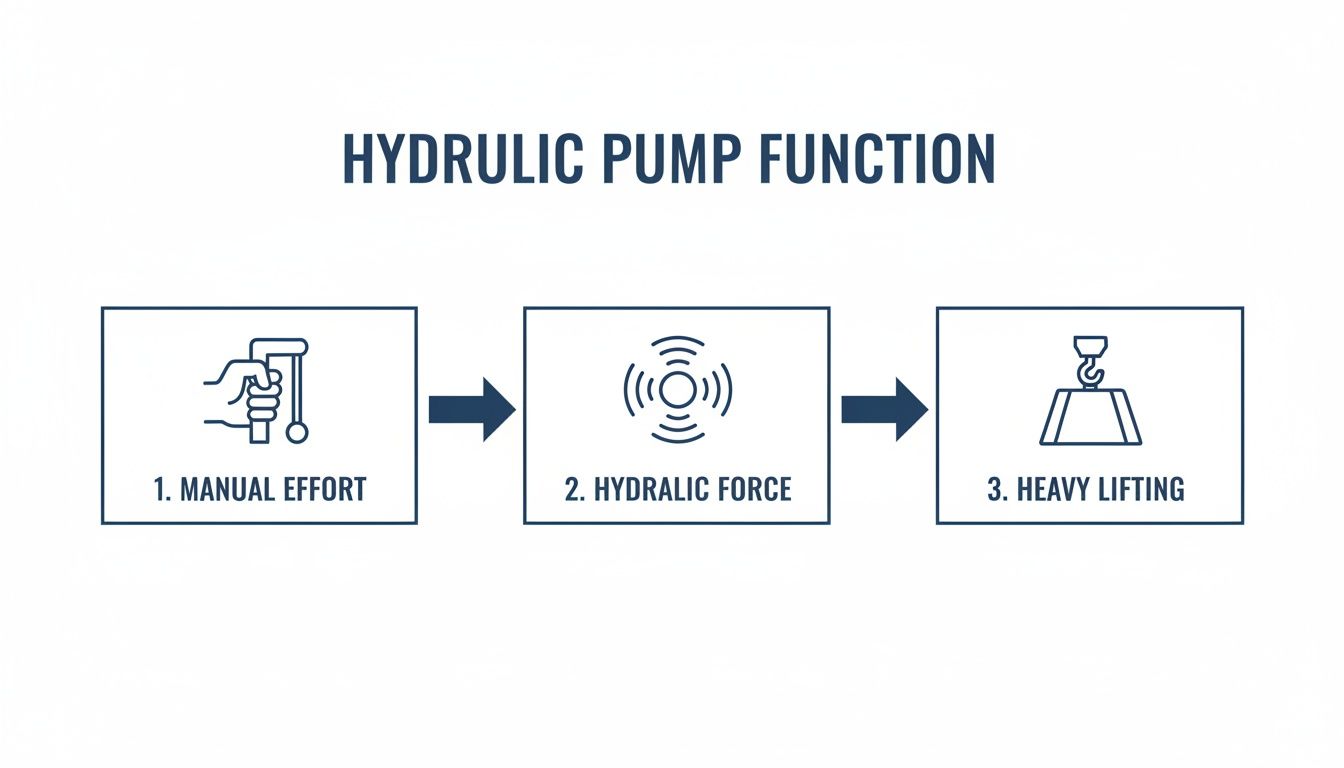

This is how simple manual work is transformed into serious hydraulic force, as you can see in the diagram below.

The image clearly shows how a small, manageable input from an operator is converted into a powerful output, capable of heavy lifting and actuation.

Single-Acting vs Double-Acting Pumps

The final piece of the puzzle is understanding how the handle’s movement translates into action. This brings us to the two main designs you’ll encounter.

- Single-Acting Pumps: These are the most common and straightforward. They only build pressure and create flow in one direction of the handle stroke—usually when you push down. The return stroke is just for drawing in the next gulp of oil.

- Double-Acting Pumps: These are a bit more sophisticated and efficient. They are designed to deliver pressurised fluid on both the push and pull strokes of the handle. This clever arrangement of pistons and check valves essentially doubles the pump’s output for the same amount of operator movement.

Getting to grips with this fundamental difference is the first step in choosing the right pump for your application. For a closer look at the components that make this possible, you might find our guide to piston pumps interesting.

If you’re unsure which pump action is right for your system, give our team a call on 01724 279508 or send us a message. We’re here to help.

Choosing Between Single-Acting and Double-Acting Pumps

Once you’ve got your head around the basics of how a hydraulic hand pump creates force, the next big decision is picking the right mechanism for your particular job. Not all hand pumps work the same way, and the most fundamental difference is whether they are single-acting or double-acting. This choice will have a direct impact on your system’s speed, efficiency, and even how it feels to operate.

It’s not about which one is better in general, but which one is better for your application. You’re essentially choosing between simplicity and speed, or fine control versus sheer output. Getting this right from the start means your equipment will perform just as you need it to, whether that’s delivering slow, deliberate force or achieving much faster cycle times.

The Single-Acting Pump Explained

The single-acting hydraulic hand pump is the simpler and more common of the two designs. It generates flow and pressure on only one stroke of the handle – almost always the downstroke. When you push the handle down, you’re doing the work. The upstroke is just a recovery motion, drawing a fresh charge of oil from the reservoir, ready for the next power stroke.

A good analogy is a basic bicycle pump. You push down to force air into the tyre; pulling up just refills the pump’s chamber for the next push. It’s a straightforward, one-way action.

This no-frills design makes single-acting pumps fantastic for applications where precision and control are more important than speed. They are a perfect fit for tasks like:

- Lifting: Slowly and safely raising a piece of equipment, like a mobile plant attachment or a vehicle on a small workshop lift.

- Clamping: Applying a steady, controlled force to hold a workpiece securely in a jig.

- Pressing: Operating a small workshop press where the operator needs to feel the pressure build up gradually.

Because they are mechanically simpler, with fewer internal check valves and seals, single-acting pumps are often more cost-effective and can be exceptionally durable. You might expect a standard single-acting pump for a small press to cost between £150 and £300, offering a reliable and affordable solution.

The Double-Acting Pump Explained

In contrast, a double-acting pump is engineered for one thing: getting the job done faster. As its name implies, it delivers pressurised fluid on both the push and pull strokes of the handle. This is achieved through a more clever arrangement of internal pistons and check valves, ensuring that no movement is ever wasted.

Every time you move the handle—down or up—it is actively pushing oil into the hydraulic system. This effectively doubles the pump’s output for the same amount of operator effort, making things happen significantly quicker.

The primary advantage of a double-acting pump is its ability to slash cycle times. By delivering fluid on both strokes, it moves hydraulic cylinders and actuators much faster, making it the superior choice for high-volume or time-sensitive operations.

This boost in speed makes double-acting pumps the go-to choice when efficiency is the name of the game. They really shine in applications like hydraulic presses where an operator needs to extend a cylinder quickly, or in test rigs where a large volume of fluid needs to be moved manually. While they are a bit more complex and often carry a higher price tag, the time saved can be a crucial performance benefit.

A Head-to-Head Comparison

To make the choice crystal clear, let’s put the two pump types side-by-side. Seeing the key differences laid out like this will help you match the right pump to your specific goals and system requirements.

Single-Acting vs. Double-Acting Hand Pump Comparison

| Feature | Single-Acting Pump | Double-Acting Pump |

|---|---|---|

| Operation | Delivers fluid on a single stroke (usually downstroke). | Delivers fluid on both push and pull strokes. |

| Speed | Slower, as the return stroke is non-productive. | Significantly faster, with continuous fluid output. |

| Efficiency | Lower overall efficiency due to the idle return stroke. | Higher efficiency as both movements are productive. |

| Complexity | Simpler design with fewer internal components. | More complex internal valve and piston arrangement. |

| Best For | Control-focused tasks like precise lifting or clamping. | Speed-focused tasks like operating presses or testers. |

| Cost | Generally more affordable and cost-effective. | Typically has a higher initial purchase price. |

At the end of the day, the right hydraulic hand pump is the one that aligns with your priorities. If your work demands careful, measured force and budget is a key factor, the robust simplicity of a single-acting pump is probably your best bet. However, if time is money and you need to get things moving quickly, investing in a double-acting pump will pay for itself in productivity gains.

For expert advice on selecting the ideal pump for your hydraulic system, phone 01724 279508 today, or send us a message and our technical team will be happy to help.

Getting to Grips with Key Pump Specifications

Choosing the right hydraulic hand pump means getting past the catalogue pictures and digging into the numbers. For engineers, MRO teams, and OEMs, these specs are the difference between a pump that works flawlessly and one that constantly struggles. Let’s break down what these core parameters really mean in practical terms, so you can make a truly informed choice.

Maximum Operating Pressure

If there’s one number you can’t ignore, it’s the Maximum Operating Pressure, measured in bar. Think of this as the pump’s absolute red line. Pushing past this limit is asking for trouble—you risk blowing seals, damaging internal parts, or even causing the pump body to fail catastrophically.

For instance, a pump rated to 250 bar will handle most common industrial and agricultural jobs just fine. But if you’re working with high-tonnage presses or bolt tensioning equipment, you’ll be looking for something much beefier, often rated at 700 bar or higher. A good rule of thumb is to always select a pump with a pressure rating that comfortably exceeds your system’s day-to-day working pressure. That safety margin is non-negotiable.

Displacement Per Stroke

Next up is Displacement per Stroke, usually given in cubic centimetres (cm³). This tells you precisely how much hydraulic fluid the pump shifts with one full pull or push of the handle. More displacement means more oil moved, which translates directly to faster cylinder movement.

But it’s not quite that simple; there’s a trade-off. A pump with a large displacement (say, 25 cm³/stroke) will extend a ram quickly, but it’s going to demand a lot more elbow grease from the operator. On the other hand, a pump with a small displacement (like 2.5 cm³/stroke) is much easier to operate but will require far more strokes to get the job done. This is why “two-speed” pumps are so popular—they give you a high-flow, low-pressure stage to quickly take up the slack, then automatically switch to a low-flow, high-pressure stage for the heavy lifting.

A Quick Calculation for Real-World Performance

Displacement isn’t just a number on a data sheet; you can use it to predict performance. To figure out how many strokes you’ll need to fully extend a cylinder, you first need to calculate the cylinder’s total volume (its area multiplied by its stroke length). Then, just divide that volume by the pump’s displacement.

- Formula: Strokes Needed = Cylinder Volume (cm³) / Pump Displacement (cm³/stroke)

Reservoir Capacity and Materials

The pump’s Reservoir Capacity, measured in litres, dictates how much hydraulic oil is on hand. The tank needs to be big enough to hold all the fluid in the system when the cylinders are fully retracted, with an extra 10-20% spare. This extra capacity is vital for cooling and preventing the oil from foaming up (aeration). A small, built-in reservoir is perfect for a portable tool, but a larger, stationary system will almost certainly need a separate tank.

The history of UK hydraulic pumps is deeply entwined with our industrial and agricultural heritage. Back in the 1940s, Dowty’s hand pumps were a game-changer for British farming, and by 1950, over 70% of tractors relied on hydraulic systems. These simple pumps allowed an average farm to lift up to 2 tonnes, boosting productivity by as much as 40% over old-school mechanical methods. Here in North Lincolnshire, where MA Hydraulics is based, that legacy continues to support modern agriculture. We stock gear pumps from industry leaders like Vivoil and OMT that can deliver flows up to 100 L/min at 250 bar—perfect for today’s powerful ploughs and harvesters. You can read more about this fascinating history in the Dowty Heritage archives.

Finally, don’t overlook the materials and port sizes.

- Materials: A pump with a steel body is built to withstand the knocks and abuse of a harsh industrial site. For mobile or portable tools, a lighter-weight aluminium body is often the smarter choice.

- Port Sizes: In the UK, you’ll almost always find BSP (British Standard Pipe) threads. Double-checking that the port size matches your hoses and fittings is a simple step that prevents frustrating, messy leaks down the line.

By carefully working through these key specs, you can choose a hydraulic hand pump that not only meets your performance needs but also delivers the reliability your operation depends on. For a closer look at our component data sheets, feel free to browse the Vivoil catalogues library.

Need a hand matching these specifications to your system? Give us a call on 01724 279508 today, or send us a message.

Getting it Right: Installation and Troubleshooting

A good quality hydraulic hand pump is built to last, but its real-world performance and lifespan really come down to proper installation and a bit of common-sense maintenance. Get the setup right from the start, and you’ll sidestep a whole world of future headaches. But even the best-installed pump can hit a snag, so knowing how to read the signs and troubleshoot common issues is a vital skill.

A Solid Start: Installation Done Right

Proper installation isn’t just about hooking up a few hoses. It’s about giving the pump a stable, stress-free foundation to do its job for years to come. Cutting corners here is a false economy, almost guaranteed to cause leaks, premature wear, or even safety problems later on.

First up, secure mounting is non-negotiable. The pump needs to be bolted down firmly to a flat, rigid surface. If the surface can flex or vibrate when you’re pumping, that movement puts stress on all the pipework and fittings, which is a leading cause of nuisance leaks.

Next, get the hose and pipe connections spot on. In the UK, you’ll most likely be dealing with BSP threads, so make sure you’re using the right fittings. Tighten them to the manufacturer’s torque specs – and this is important. It’s just as easy to cause a leak by over-tightening and damaging a seal as it is by leaving a connection too loose.

Finally, don’t forget the most important safety net: a pressure relief valve. This isn’t an optional extra; it’s a critical component. Set it to the system’s maximum safe operating pressure. This little device is what stands between you and a dangerously over-pressurised system that could blow a hose or damage an actuator.

The Quick Maintenance Checklist

A few simple, regular checks are the cheapest insurance you can buy for your hydraulic hand pump. This isn’t about spending hours; it’s about catching small problems before they become big, expensive ones.

- Fluid Check: Keep an eye on the oil level in the reservoir and top it up with clean, new fluid of the right grade (like ISO VG32) when needed. The oil itself tells a story. If it looks milky, you’ve got water contamination. If it’s dark or smells burnt, it’s overdue for a change.

- Leak Patrol: Walk the system and visually check every connection, seal, and hose for any sign of oil weeping or dripping. A tiny leak is a big warning sign that a seal is failing or a fitting needs attention.

- Seal Inspection: Take a close look at the main piston rod seal. It should be clean and intact. If it’s damaged, it won’t just leak oil out; it will let dirt and moisture in, which is poison for any hydraulic system.

- Smooth Operation: The pump handle should have a smooth, consistent feel through its entire stroke. If it starts to stick, jerk, or feel unusually stiff, that’s a clue that there might be dirt inside or a mechanical issue developing.

Solving Common Pump Problems

Even with the best care, things can go wrong. Here’s a quick field guide to figuring out what’s happening when your hand pump starts acting up.

Problem: The pump handle feels spongy and just won’t build pressure.

The usual suspect: Air trapped in the system. Hydraulic fluid is practically incompressible, but air is. That trapped air is what gives you that spongy, ineffective feeling.

The fix: You need to bleed the system. With no load on the cylinder, operate the pump for several full strokes. You might need to crack open a fitting at the highest point in the circuit just a tiny bit to let the air hiss out. As soon as you see a solid stream of oil, tighten it back up.

Problem: You can see fluid leaking, usually around the handle or the main pump body.

The usual suspect: This is a classic symptom of worn or damaged seals. Age, contaminated oil, or running the system at pressures way over its rating can cause seals to degrade and fail.

The fix: It’s time for a rebuild. The pump will need to be carefully dismantled and the old seals replaced. Buying a seal kit for your specific pump model is the easiest and most cost-effective way to do this. Just be absolutely certain everything is spotlessly clean before you put it back together.

Problem: The pump feels like it’s working, but it struggles to lift a load or builds pressure very, very slowly.

The usual suspect: This often points to an internal leak. A tiny piece of debris might be stuck in a check valve, preventing it from sealing properly, or a piston seal might be worn out. Contaminated fluid is a major cause of this.

The fix: Start by checking the condition of your hydraulic fluid. If it’s dirty, you’ve found your likely problem. The entire system needs to be drained, flushed, and refilled with clean oil. If that doesn’t solve it, the pump’s internal valves and seals are the next port of call for inspection and replacement.

If you hit a problem you can’t solve or need a specific part for your hydraulic hand pumps, our expert team is ready to help. Give us a call on 01724 279508 or send us a message for hands-on technical support and advice.

Your Hydraulic Hand Pump Questions Answered

When you’re out in the field or on the workshop floor, practical questions about hydraulic hand pumps always come up. Getting clear, no-nonsense answers can save a lot of head-scratching and prevent some common slip-ups. Let’s tackle some of the most frequent queries we hear.

What Hydraulic Fluid Should I Use?

The golden rule is simple: always check the manufacturer’s spec sheet first. That’s your definitive guide for your specific pump.

That said, as a general rule of thumb, most standard hand pumps you’ll find in the UK work brilliantly with ISO VG22 or ISO VG32 mineral-based hydraulic oils. Getting the viscosity right is absolutely critical. It’s what guarantees the pump works smoothly, keeps all the moving parts properly lubricated, and handles the typical British temperature swings without any drama. Fluid that’s too thick will feel like you’re pumping treacle, and if it’s too thin, you risk poor lubrication and sealing, which leads to early wear and tear.

Can I Use a Hand Pump as a Backup for a Powered System?

Absolutely. In fact, it’s one of their most popular and valuable uses.

Plumbing a manual hand pump into a powered circuit is a smart way to build in a failsafe. With the right valving in place, the hand pump can take over for emergency operations or give you delicate manual control if the main power unit fails or is switched off for maintenance. You see this all the time on mobile machinery, where a hand pump lets an operator safely lower a boom or attachment to the ground after an engine cuts out. It’s also a go-to solution in industrial settings for making tiny, precise adjustments that a high-flow powered pump would simply overshoot.

How Do I Bleed Air from a Hydraulic Hand Pump System?

That spongy, unresponsive feeling in the handle? That’s the classic sign of trapped air. Hydraulic fluid itself doesn’t compress, so even a tiny bubble of air in the lines will make the pump feel sluggish and ineffective.

To bleed the system, start by taking any load off the actuator. Loosen the reservoir cap so air can get out, then slowly work the pump handle through several full strokes. This cycles the fluid and pushes the trapped air back to the tank where it belongs. If you have a stubborn air pocket, you might need to carefully “crack” open a fitting at the highest point in the system while pumping gently. As soon as you see a solid, bubble-free stream of oil, tighten it back up securely.

What is the Typical Lifespan of a Hydraulic Hand Pump?

With a bit of proper care, a quality hand pump from a good manufacturer will give you years of reliable service, even in harsh conditions. Longevity really just comes down to simple, consistent maintenance.

Keeping an eye on the fluid level and making sure it’s clean is half the battle. Regular checks for leaks and making sure you never push the pump beyond its rated pressure will dramatically extend its working life. The first things to wear are usually the seals, but these are typically cheap and easy to replace as part of a basic service kit.

If you’ve got more specific questions or need a hand with your hydraulic hand pumps, our team is always ready to help. Give us a call on 01724 279508, or send us a message for expert advice.

Let MA Hydraulics Help You Get It Right the First Time

Choosing the right hydraulic hand pump isn’t just about ticking boxes on a spec sheet. It’s about getting the right heart for your system, a decision that directly affects its performance, reliability, and lifespan. While this guide gives you a solid foundation, my years of experience have taught me that the real magic happens when you match the right component to the specific job.

That’s where we come in. The team at MA Hydraulics lives and breathes fluid power. We’re here to help you navigate the options and select the ideal pump, whether you need a simple off-the-shelf unit or a fully integrated component for a custom-built power pack.

More Than Just a Supplier – A Complete System Partner

We don’t just shift boxes. Our real value lies in providing complete, thought-out solutions that work for you in the real world. Think of us as your single source for everything you need to build or repair a hydraulic system.

We can supply all the necessary components, ensuring they’re all perfectly matched:

- Robust reservoirs and tanks built to last

- A comprehensive range of control valves

- Tough, reliable hoses and precision fittings

- High-quality filters to keep your system clean and protected

Taking this big-picture view means every part works together flawlessly, giving you the performance and longevity you need. From our base in Scunthorpe, we’re set up to provide exceptional support and get components to you fast.

At MA Hydraulics, we combine deep product knowledge with a hands-on, practical approach. We’re not just selling parts; we’re building partnerships. Our goal is to help your machinery perform at its absolute best, making sure you get a reliable, high-quality solution that your system deserves.

Let our experience work for you. Whether you’re designing a new system from scratch, carrying out essential maintenance, or just need a reliable part in a hurry, we’re ready to help.

For expert advice and to tap into our huge stock of hydraulic components, get in touch with MA Hydraulics Ltd. Phone 01724 279508 today, or send us a message to chat through your requirements with our technical team.