At its most basic, a hydraulic power unit (HPU) is the engine room of any hydraulic system. It's the core component that takes a primary power source—usually an electric motor or a diesel engine—and converts that energy into hydraulic muscle.

Just think of it like the heart in the human body. The heart pumps blood at a specific pressure to keep everything working; an HPU does the same thing, but with hydraulic fluid, generating the flow and pressure needed to power everything from giant factory presses to the arm of an excavator. It’s the central nervous system and the powerhouse rolled into one.

Understanding the Role of a Hydraulic Power Unit

The fundamental job of an HPU is to transmit, control, and distribute energy. It takes the rotational energy from its motor or engine and uses a pump to pressurise hydraulic fluid (a special type of oil). This highly pressurised fluid is then directed through a network of hoses and valves to where the work needs to be done, such as moving a hydraulic cylinder or spinning a hydraulic motor.

The principle at play is surprisingly simple, something you’ve probably seen in a basic car jack. Pumping the handle applies a small amount of force, which pressurises the fluid inside. That pressurised fluid then acts on a much larger piston, effortlessly lifting a multi-tonne car. This concept, known as Pascal's Law, is exactly what an HPU exploits, just on a much bigger and more sophisticated scale.

Why Are HPUs So Widely Used?

Hydraulics are everywhere for a good reason: power density. An HPU can pack an incredible amount of force into a remarkably small footprint, something purely mechanical or electrical systems often can't match. This makes them the go-to solution for any application that needs serious muscle for lifting, pressing, pulling, or clamping.

They bring several key advantages to the table:

- Massive Force Amplification: Just like with the car jack, HPUs excel at multiplying a small input force into a huge output force.

- Precision Control: Modern hydraulic systems give operators incredibly fine control over speed, force, and position, which is essential in automated manufacturing and robotics.

- Built to Last: Hydraulic components are famously tough. Designed for harsh industrial environments, they are known for their ruggedness and long operational life, provided they’re looked after.

To give you a better sense of how it all works, let's break down the core jobs an HPU performs and which parts are responsible for them.

Core Functions of a Hydraulic Power Unit

| Function | Primary Component(s) | Purpose |

|---|---|---|

| Energy Conversion | Motor/Engine & Pump | To convert electrical or mechanical energy into hydraulic energy (pressurised fluid). |

| Fluid Storage & Conditioning | Reservoir (Tank) & Filter | To hold a supply of clean hydraulic fluid, cool it, and remove contaminants. |

| Pressure & Flow Control | Valves (Relief, Directional) | To regulate the system pressure, direct the fluid’s path, and control actuator speed. |

| System Monitoring | Gauges & Sensors | To provide real-time feedback on pressure, temperature, and fluid levels for safe operation. |

This table shows that an HPU is more than just a pump and motor; it’s a complete, self-contained system designed for one purpose: to deliver controlled hydraulic power precisely where it’s needed.

Ultimately, whether it’s tilling a field with agricultural machinery or operating complex robotics on a factory floor, the HPU is the unseen workhorse making it all possible. Getting to grips with its function is the first step toward understanding just how powerful and versatile hydraulic technology truly is.

Understanding the Core Components of an HPU

A hydraulic power unit might seem like a complex beast, but it’s really just a team of specialist components working in perfect harmony. Each part has a very specific job, and when you understand how they interact, you start to appreciate the elegance behind the HPU’s raw power and reliability.

Think of it less as a single machine and more as a coordinated system, purpose-built to generate and control immense force. At its heart, every hydraulic power unit—from a compact unit on a tipper truck to a huge industrial power pack—is built on the same foundational parts.

The Prime Mover: The Engine Room

The whole process of generating hydraulic power kicks off with the prime mover. This is simply the initial source of energy that gets everything moving. For stationary industrial setups, it’s usually an electric motor; for mobile machinery out in the field, it’s typically a diesel or petrol engine.

Its one and only job is to provide the rotational force needed to drive the hydraulic pump. The prime mover doesn’t create hydraulic power itself; it supplies the mechanical horsepower that the pump will convert. Getting this match right is absolutely critical—an undersized motor will struggle and burn out, while an oversized one is just a waste of energy and money.

The Hydraulic Pump: The Heart of the System

If the prime mover is the engine room, then the hydraulic pump is undoubtedly the heart. It draws hydraulic fluid from the reservoir and shoves it into the system, creating flow. This is the precise moment mechanical energy is converted into hydraulic energy.

Pumps come in a few common flavours—gear, vane, and piston pumps are the ones you’ll see most often—and each has its own strengths. The type of pump you choose dictates the system’s maximum pressure and flow rate, which ultimately defines its power output.

It’s crucial to remember that pumps create flow, not pressure. Pressure only builds when that flow meets resistance, like when it’s trying to lift a heavy cylinder. Grasping this distinction is fundamental to understanding how all hydraulic systems work.

The Reservoir: The System’s Lungs

The reservoir, or tank, does a lot more than just hold the hydraulic fluid. It’s an unsung hero, playing several vital roles in keeping the entire hydraulic power unit healthy and running smoothly.

A well-designed reservoir helps to:

- Cool the Fluid: As oil circulates, it heats up. The large surface area of the tank acts like a radiator, allowing this heat to dissipate into the air.

- Separate Contaminants: It gives heavier particles like dirt and metal filings a chance to settle at the bottom, safely away from the pump’s intake.

- Release Trapped Air: The reservoir provides a calm space for any entrained air to escape from the fluid before it gets sucked back into the system, preventing that spongy, inefficient performance nobody wants.

Control Valves: The Brain and Nervous System

Valves are the decision-makers. They are the brain of the operation, directing the pressurised fluid exactly where it needs to go, precisely when it needs to get there, and at the right pressure and flow. Without valves, you’d just have a pump creating an endless, uncontrolled gush of oil.

You’ll typically find three main types of valves in an HPU:

- Directional Control Valves: These are the switches, responsible for starting, stopping, and changing the direction of the fluid to operate cylinders and motors.

- Pressure Control Valves: These are the managers, keeping system pressure in check. This includes relief valves, which act like a safety fuse to prevent dangerous over-pressurisation.

- Flow Control Valves: These act like a tap, regulating the speed of motors and cylinders by controlling how much fluid they receive.

Filters and Accumulators: The Support Crew

Finally, a couple of other key components are essential for protection and peak performance. Filters are the system’s guardians, tirelessly capturing the harmful contaminants that can wreck expensive pumps and valves. They are your first and best line of defence against premature failure.

An accumulator, on the other hand, acts like a rechargeable battery for the hydraulic system. It’s a pressure vessel that stores fluid under pressure, ready to be discharged on demand. This allows the system to react instantly to sudden needs for high flow, absorb pressure spikes, or even provide emergency power if the prime mover cuts out. To learn more, you can explore the role of hydraulic accumulators in our detailed guide.

This reliance on efficient hydraulic systems is a growing trend across British industry. The UK hydraulic power unit market is projected to grow at a compound annual growth rate (CAGR) of 5.1% as of 2025, a figure driven by the modernisation of manufacturing and major upgrades in sectors like defence and offshore energy. It really underscores just how much value businesses place on reliable, well-engineered hydraulic solutions.

How to Size and Specify Your Hydraulic Power Unit

Choosing the right hydraulic power unit isn’t about getting the most powerful one on the market; it’s about finding the one that’s a perfect match for your application. If it’s undersized, it will constantly be fighting to keep up, leading to poor performance and, eventually, a much shorter lifespan. Go too big, on the other hand, and you’re just wasting energy and driving up your running costs for no good reason.

Getting this specification right from the very beginning is the single most important thing you can do to ensure your hydraulic system is reliable, efficient, and built to last. It’s a logical process, really—just a matter of matching the HPU’s capabilities to the demands of the job. Let’s walk through the essential calculations step-by-step.

Determine Required Flow and Pressure

First things first, you need to pin down the two most critical numbers for your system: the required flow rate and pressure. These aren’t arbitrary figures; they’re dictated entirely by the work your machine needs to do.

- Pressure (bar or PSI): Think of this as the force your system can deliver. You’ll need to work out the maximum force required by your actuator—like a hydraulic cylinder—to lift a load or complete its task.

- Flow Rate (Litres Per Minute or LPM): This is all about speed. A higher flow rate means a cylinder will extend faster or a hydraulic motor will spin quicker.

A good example is a workshop press. It needs incredibly high pressure to generate immense crushing force, but the movement itself can be slow and controlled, so a low flow rate is perfectly fine. In contrast, a hydraulic winch on a recovery vehicle needs both high pressure to lift heavy loads and a high flow rate to reel the cable in quickly.

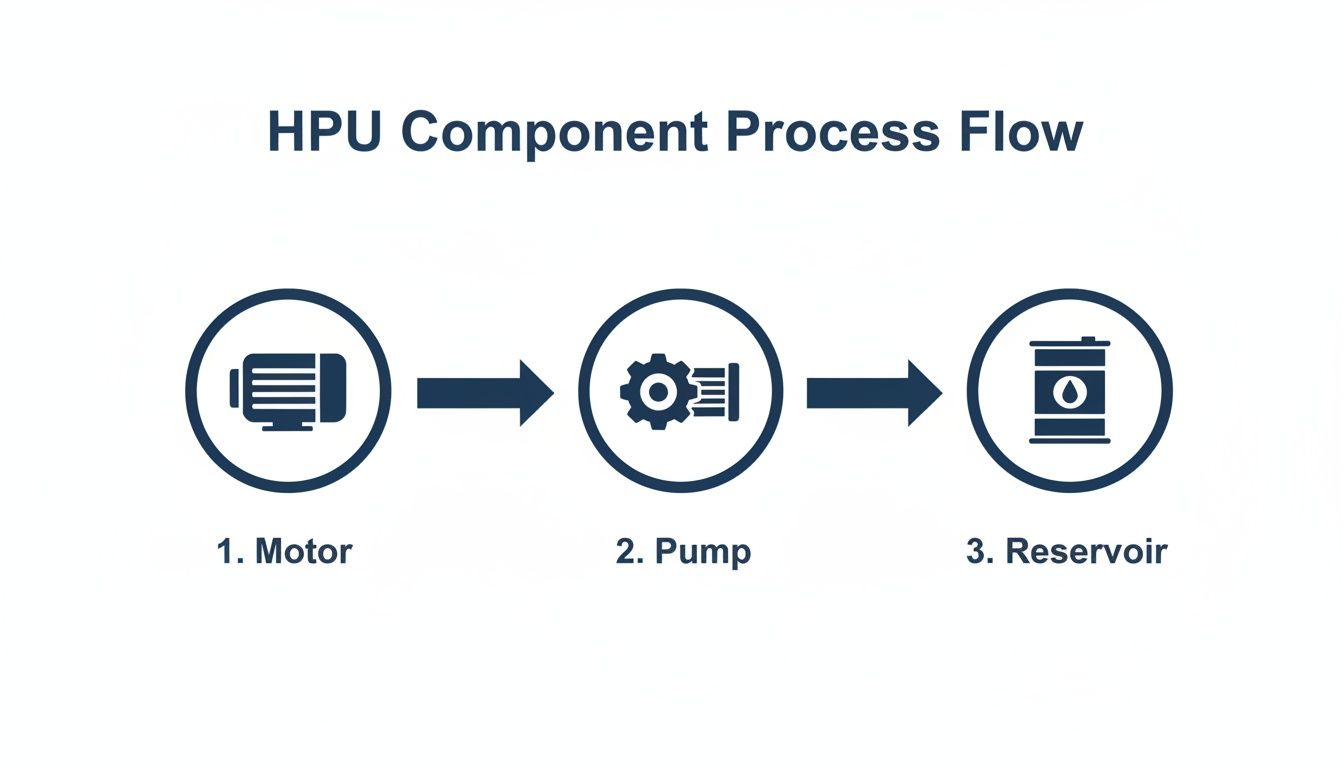

The journey of power within an HPU starts with the motor, converting mechanical energy into hydraulic muscle.

As you can see, it’s a straightforward conversion: the prime mover’s mechanical energy drives the pump, which creates the hydraulic flow. The reservoir then stores and conditions this fluid, ready for action.

Calculate Prime Mover Horsepower

Once you have your target pressure and flow, you can figure out how much power your prime mover (the electric motor or engine) needs. This calculation ensures the motor has enough grunt to drive the pump without being overloaded, which is a fast track to burnout.

A handy rule-of-thumb formula for electric motors is:

Horsepower (HP) = (Pressure in PSI x Flow in GPM) / 1714

(Note: To convert LPM to Gallons Per Minute (GPM), divide by 3.785)

Let’s imagine a system needing 2000 PSI and 20 LPM (which is about 5.3 GPM). The calculation would point to a requirement of roughly 6.2 HP. In the real world, you’d select the next standard motor size up—most likely a 7.5 HP motor—to give yourself a safe performance margin. Selecting the right motor and pump is a critical pairing; you can see a great example of a matched Vivoil pump and motor unit here.

Key Takeaway: Always size your prime mover with a bit of a buffer. This accounts for small inefficiencies in the system and stops the motor from constantly running at its absolute limit, which will dramatically extend its working life.

Select the Right Reservoir Size

The reservoir is much more than just a holding tank for oil. It plays a vital role in managing heat and keeping the fluid clean. A widely accepted industry guideline is to size the reservoir to hold three to five times the pump’s flow rate in LPM.

So, for our 20 LPM pump, a reservoir somewhere between 60 and 100 litres would be ideal. A larger tank provides more surface area for heat to dissipate naturally and gives any contaminants in the fluid more time to settle at the bottom. If your HPU is going to be working hard with a high duty cycle or operating in a hot environment, you should definitely lean towards a larger reservoir or even consider adding a dedicated oil cooler to prevent overheating.

This kind of careful specification is becoming more important than ever. The global hydraulic power unit market is projected to grow from USD 14.0 billion to USD 24.2 billion by 2036. Closer to home, the UK market is expanding at a 4.9% CAGR, largely driven by demand from the defence and offshore energy sectors. It’s interesting to note that units with power ratings between 7.5 kW and 75 kW hold a dominant 48.2% market share, showing just how common this capacity range is across all industries.

Choosing Between Mobile and Industrial HPUs

A hydraulic power unit is never a ‘one-size-fits-all’ purchase. Think about it: the power pack needed for a factory press running non-stop has a completely different job to the one driving the tipper on a lorry. Choosing the right type isn’t just a detail—it’s fundamental. Putting a unit designed for one world into the other is a recipe for poor performance and, eventually, failure.

The decision really comes down to two very different design philosophies: mobile and industrial. Each one is engineered from the ground up to tackle a specific set of challenges, from how it gets its power and how much space it takes up, to how much of a beating it can take from the environment. Getting your head around these differences is the first real step towards specifying a system that will do its job reliably and efficiently.

The Mobile Hydraulic Power Unit: Compact and Resilient

Mobile hydraulic power units are the tough, compact workhorses you’ll find on everything from diggers and tractors to recovery winches and boat lifts. Their entire design is dictated by a simple fact: they have to work flawlessly on the move, often in pretty grim and unpredictable conditions.

That reality influences every single component. With no mains socket in sight, they’re typically powered by 12V or 24V DC electric motors running off a vehicle’s battery, or sometimes a small petrol or diesel engine. Space is almost always tight, so these units are built to be as small and light as possible. You’ll often see smaller reservoirs and clever, integrated component manifolds to keep the footprint tiny.

And because they’re constantly being rattled, bumped, and shaken, these HPUs are built tough. Every part is chosen for its ability to withstand constant vibration, and the whole assembly is put together to be a solid, robust block of power.

Key Takeaway: The defining feature of a mobile hydraulic power unit is its ability to pack a serious punch into a small, self-contained, and incredibly durable package. It’s built to handle the rough-and-tumble of an outdoor, on-the-go work environment.

The Industrial Hydraulic Power Unit: Built for Endurance

On the other hand, industrial hydraulic power units are the marathon runners of the hydraulics world. You’ll find them tucked away in factories, workshops, and processing plants, where they’re expected to run for thousands of hours, day in and day out, without missing a beat.

Here, the primary power source is almost always a beefy AC electric motor, wired straight into the building’s mains supply for a steady, endless stream of power. Since they don’t have to be squeezed onto a vehicle chassis, industrial HPUs are usually much larger. This allows for bigger reservoirs, which are absolutely crucial for getting rid of the heat that builds up during those long, continuous shifts.

Ease of maintenance and access are also major design drivers. Components are typically laid out with space around them so that technicians can easily get in for routine checks, filter changes, and repairs, keeping downtime to an absolute minimum. Industrial units are all about stability, cooling, and the sheer longevity needed for gruelling production schedules.

Mobile vs Industrial Hydraulic Power Units Key Differences

To make the distinction crystal clear, this table breaks down the core design differences between the two main types of hydraulic power unit.

| Feature | Mobile Hydraulic Power Unit | Industrial Hydraulic Power Unit |

|---|---|---|

| Power Source | Typically 12V/24V DC motors or small engines. | Primarily AC electric motors (single or 3-phase). |

| Design Footprint | Compact, lightweight, and integrated for tight spaces. | Larger, with an open layout for cooling and maintenance. |

| Duty Cycle | Designed for intermittent, high-power bursts. | Built for continuous, long-duration operation. |

| Environment | Rugged build to withstand vibration, shock, and weather. | Designed for stable, controlled indoor environments. |

| Cooling | Relies on smaller reservoirs and ambient airflow. | Uses large reservoirs and often dedicated coolers. |

At MA Hydraulics, we operate comfortably in both worlds. We assemble nimble Hydronit mini power packs that are perfect for mobile applications, and we design and build robust, bespoke industrial units up to 11 kW that are tailored to the specific demands of a factory floor.

This dual expertise is vital. Both sectors are growing, and you can see a great example in the automotive world. UK automotive hydraulics systems are a huge driver for mobile units, with the market expected to hit USD 2,153.7 million by 2030. This points to big opportunities not just with equipment manufacturers but also in the booming aftermarket service sector. You can dig deeper into these UK automotive hydraulics market trends on GrandViewResearch.com.

Essential HPU Maintenance and Troubleshooting Tips

A hydraulic power unit that’s well looked after is one you can rely on. Think of proactive upkeep not as a chore, but as the single best way to sidestep unexpected downtime. A bit of regular attention can save your operation thousands in lost productivity and emergency repairs, much like a car needs its oil changed to keep the engine healthy.

It’s all about shifting your mindset from “fix it when it breaks” to spotting trouble before it starts. Regular checks give your team the chance to catch small issues—a weeping hose fitting, a slight change in the pump’s hum—before they escalate into a full-blown system failure. This consistent monitoring is the bedrock of any solid maintenance plan.

A Practical Preventative Maintenance Checklist

Getting into a routine is the secret to successful HPU maintenance. Here’s a straightforward checklist of essential tasks that should form the core of your schedule. Following these steps will help ensure your hydraulic power unit runs smoothly for years to come.

- Check Fluid Level and Quality: Keep a regular eye on the reservoir’s fluid level. Running low is one of the fastest ways to damage a pump. While you’re there, look at the fluid itself—if it appears milky or foamy, you’ve got water or air contamination, both of which are serious problems.

- Monitor System Temperature: If your HPU is consistently running hotter than 82°C (180°F), that’s a major red flag. High temperatures break down hydraulic fluid, cook the seals, and dramatically shorten the life of your components. Overheating almost always points to an underlying efficiency issue.

- Inspect and Change Filters: Your filters are the first line of defence against contamination, which is the culprit behind up to 80% of all hydraulic system failures. You absolutely must stick to a strict schedule for changing the suction, pressure, and return line filters.

- Look and Listen for Leaks and Noise: A quick daily walk-around to check for leaks at fittings, seals, and hoses can save a world of hurt. At the same time, listen to the system. Any unusual noises like whining, knocking, or banging are early warnings of problems like aeration, cavitation, or a pump on its way out.

By building these simple checks into a daily or weekly routine, you’ll get a clear picture of your HPU’s health and be able to catch problems long before they turn catastrophic.

Common Problems and How to Fix Them

Even with the best maintenance plan, things can still go wrong. The key is knowing how to diagnose issues quickly. Instead of just guessing, a logical troubleshooting process will lead you straight to the root of the problem.

Key Insight: Most hydraulic issues show up as a symptom, like overheating or sluggish operation, but the real cause is often hidden elsewhere. The trick is to follow the evidence logically, always starting with the simplest possible explanation first.

This guide will walk you through the diagnostic process for some of the most common faults you’ll encounter with an HPU.

Troubleshooting System Overheating

Overheating is a clear sign that your hydraulic power unit is generating more heat than it can get rid of. This isn’t just wasted energy; it’s a direct threat to the longevity of your entire system.

- Problem: The HPU is running too hot.

- Potential Causes:

- The relief valve is set too low and is constantly dumping fluid back to the tank.

- The reservoir fluid level is too low to dissipate heat properly.

- A worn pump or motor has internal leakage, creating excess heat from friction.

- The system’s heat exchanger or cooler is clogged with dirt and grime.

- Solutions:

- Check the relief valve pressure and set it correctly.

- Top up the reservoir to the recommended level.

- If the problem continues, it’s time to investigate component wear.

- Clean the fins on the cooler. For more effective thermal management, you might consider dedicated hydraulic air coolers.

Diagnosing Low Pressure or Slow Performance

When your actuators are moving like they’re stuck in treacle or just can’t generate enough force, the issue lies with either system pressure or flow.

- Problem: The system is slow, weak, or shows low pressure.

- Potential Causes:

- The relief valve is stuck open or set incorrectly.

- The pump is worn and simply can’t generate the required flow anymore.

- There’s a significant leak, either internal or external.

- The pump is being starved of fluid because of a clogged suction strainer.

- Solutions:

- Inspect, clean, and reset the relief valve.

- Run a flow test on the pump to check its efficiency.

- Carefully inspect the entire circuit for leaks.

- Clean or, if necessary, replace the suction strainer.

By adopting this kind of structured, informed approach to maintenance and troubleshooting, you give your team the tools they need to keep your hydraulic power unit—and your entire operation—running at its best.

Your Partner for Custom Hydraulic Power Solutions

Knowing the theory behind a hydraulic power unit is one thing, but turning that knowledge into a reliable, real-world solution is a completely different challenge. This is where the textbook meets the workshop floor, and having an experienced partner can make all the difference. At MA Hydraulics, we don’t just sell components; we engineer complete hydraulic power solutions built around your exact operational needs.

Our expertise covers two main areas, allowing us to serve a huge range of UK industries with real precision. For mobile machinery where every inch of space counts, we assemble custom Hydronit mini power packs. For tough industrial settings where reliability is non-negotiable, we design and build bespoke industrial power packs up to 11 kW.

From Components to Complete Systems

When you choose MA Hydraulics, you’re tapping into decades of hands-on experience. Our team makes sure every single part of your hydraulic power unit—from the motor and pump right down to the valving and filtration—is perfectly matched. It’s this careful, detail-oriented approach that guarantees you get the best performance, efficiency, and long-term reliability from your equipment.

Whether you’re designing a brand-new machine or upgrading an existing system, a custom-built HPU gets rid of all the guesswork and compromises. It’s engineered from the ground up to deliver the exact flow, pressure, and control your application needs.

This is especially important for:

- Original Equipment Manufacturers (OEMs) who need a dependable, repeatable power source for their products.

- Design Engineers trying to solve a specific problem, whether it’s tight space constraints or unique performance demands.

- Procurement Managers looking for a solution that delivers value without cutting corners on quality.

We’re the bridge between a catalogue full of parts and a fully working, optimised system. By working closely with you, we make sure the final build doesn’t just meet your specifications—it exceeds them. The result is a power solution that feels like it was made just for your operation, because it was.

When you’re ready to turn your plans into a working reality, our team is here to help. We offer the technical support and practical advice you need to build the perfect hydraulic power unit for your next project.

Ready to build your next hydraulic power unit? Contact the MA Hydraulics team today to discuss your specific requirements.

Frequently Asked Questions

When you’re working with hydraulic power units every day, practical questions are bound to come up. We’ve put together some straightforward answers to the queries we hear most often from engineers, operators, and procurement managers to help you get the best performance from your equipment.

How Often Should I Change Hydraulic Fluid and Filters?

There’s no single, magic number for this – it really comes down to where and how you’re using your HPU. A unit humming along in a clean, climate-controlled factory floor needs a very different service schedule than one getting hammered on a dusty, damp construction site.

As a solid rule of thumb, always change the filter on a new system after its first 50 to 100 hours of run time. This initial change is crucial for catching any small contaminants left over from the manufacturing and break-in period. After that, a good baseline for filter changes is every 500 to 1,000 operating hours.

When it comes to the hydraulic fluid itself, the gold standard is to let regular oil analysis guide your decision. If you don’t have an analysis programme in place, a general guideline for industrial units is a full fluid change every 3,000 to 5,000 hours. But be realistic – if your gear is exposed to a lot of dust, moisture, or big temperature swings, you’ll need to shorten those intervals significantly.

What Is the Most Common Cause of HPU Overheating?

Overheating isn’t the problem itself; it’s a symptom. Think of it as a warning light telling you that your system is wasting energy by turning it into excess heat instead of productive work. Finding the real cause is vital to prevent serious, long-term damage.

We see a few common culprits time and time again:

- Incorrect Relief Valve Setting: If the main relief valve is set too low, it’s constantly dumping fluid back to the tank. This is a massive heat generator.

- Undersized Reservoir: The tank might simply be too small to give the fluid enough time and surface area to cool down, especially when the system is working hard.

- Internal Component Wear: A worn-out pump or motor will have more internal leakage, and that slippage creates a lot of heat through friction.

- Blocked or Dirty Cooler: It sounds simple, but an oil cooler caked in dust and grime can’t do its job of getting rid of heat.

Your first line of defence is simple: regularly check that your system pressure is set correctly and make sure any coolers are kept clean and clear.

Can I Use Any Standard AC Motor for My HPU?

Absolutely not. It’s critical that the motor is a perfect match for the hydraulic pump. Just grabbing a motor with the right horsepower rating is a recipe for trouble. You have to consider the motor’s speed (RPM), frame size, and shaft specifications – they all need to line up precisely with the pump it’s driving.

Using an undersized motor will cause it to constantly overload and burn out. On the flip side, an oversized motor is just inefficient, wasting electricity and driving up your running costs. The motor’s duty cycle also has to be up to the job you’re asking it to do.

This is exactly why getting a professionally specified power unit is so important. An expert ensures the motor, pump, and bellhousing are designed to work together as a seamless, efficient, and reliable trio that will last for years.

For expert help specifying the right components or designing a complete hydraulic power unit for your application, trust the specialists at MA Hydraulics. We source, supply, and build reliable power solutions for UK industry. Explore our hydraulic components and bespoke build services at mahydraulics.co.uk.