The HI-LO pump is useful when an operating cycle is required to run at different speeds, especially when a considerable part of the cycle is carried out with zero or far less than the actual working effort.

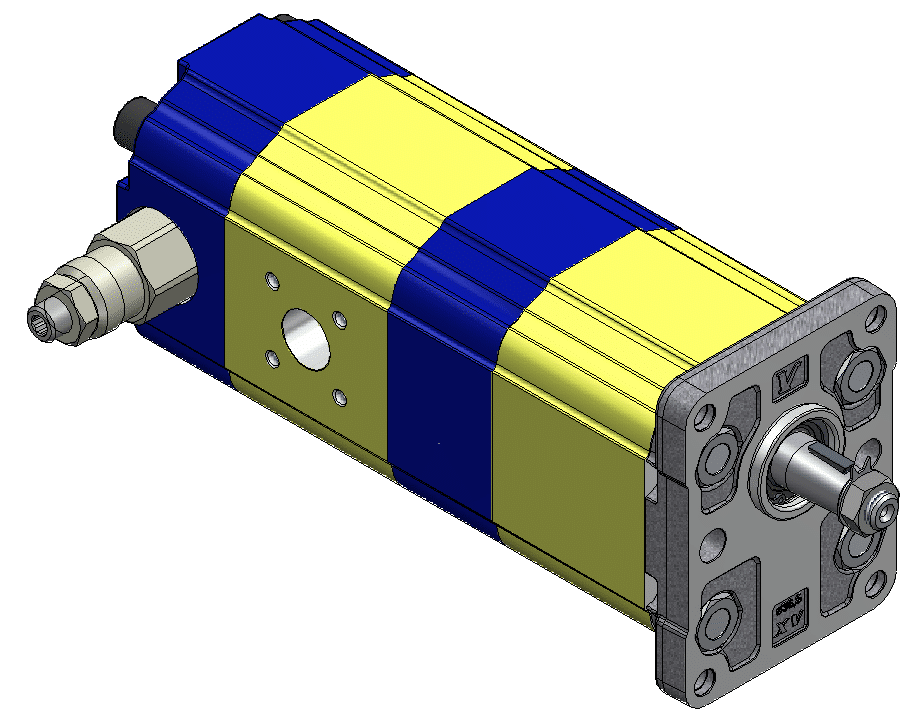

The HI-LO pump is essentially a double pump in which the drive pump is the pump dedicated to providing the high pressure; the final pump provides the low-pressure flow (added to the front pump) for fast movements.

The necessary valves have been integrated into the intermediate plate and cover:

– 3-way directional valve with external piloting

– 2-way directional check valve (guide poppet type)

Below a given pressure (decoupling pressure, set by adjusting the set screw of the valve), the flow rate delivered by the pump is the sum of the flow rate of the front and rear stages. Above the decoupling pressure, the rear stage is put into recirculation and delivers no flow; under these conditions, only the front stage operates, whose flow rate is only given by its displacement, being able to reach the maximum pressure required by the application.

The function of the diverter valve is carried out by the directional valve in the pump cover, which automatically switches the flow direction depending on the piloting: when a certain pressure is exceeded, the valve switches and opens the recirculation channel of the pump. The non-return valve closes the connection between the two stages so that only the front stage reaches maximum pressure.

Contact our experienced sales team for more details on 01724 279508 or email info@mahydraulics.co.uk.