When you're faced with connecting a 1/4 BSP fitting to a metric one, it's never a case of just screwing them together. The two standards are worlds apart in their design. A 1/4 BSP thread has its own unique pitch and profile, so you'll always need a specific adaptor to bridge the gap to a metric component, like an M12 or M14 fitting.

Getting this wrong in a hydraulic system isn't an option.

What Exactly Is a 1/4 BSP Thread?

In British engineering, especially in the world of hydraulics, British Standard Pipe (BSP) threads are everywhere. If you're working on equipment from different places or periods, being able to spot these threads correctly is your first, most crucial task. Without that basic knowledge, you're running a serious risk of damaging parts and causing high-pressure leaks.

You'll come across two main types of BSP thread:

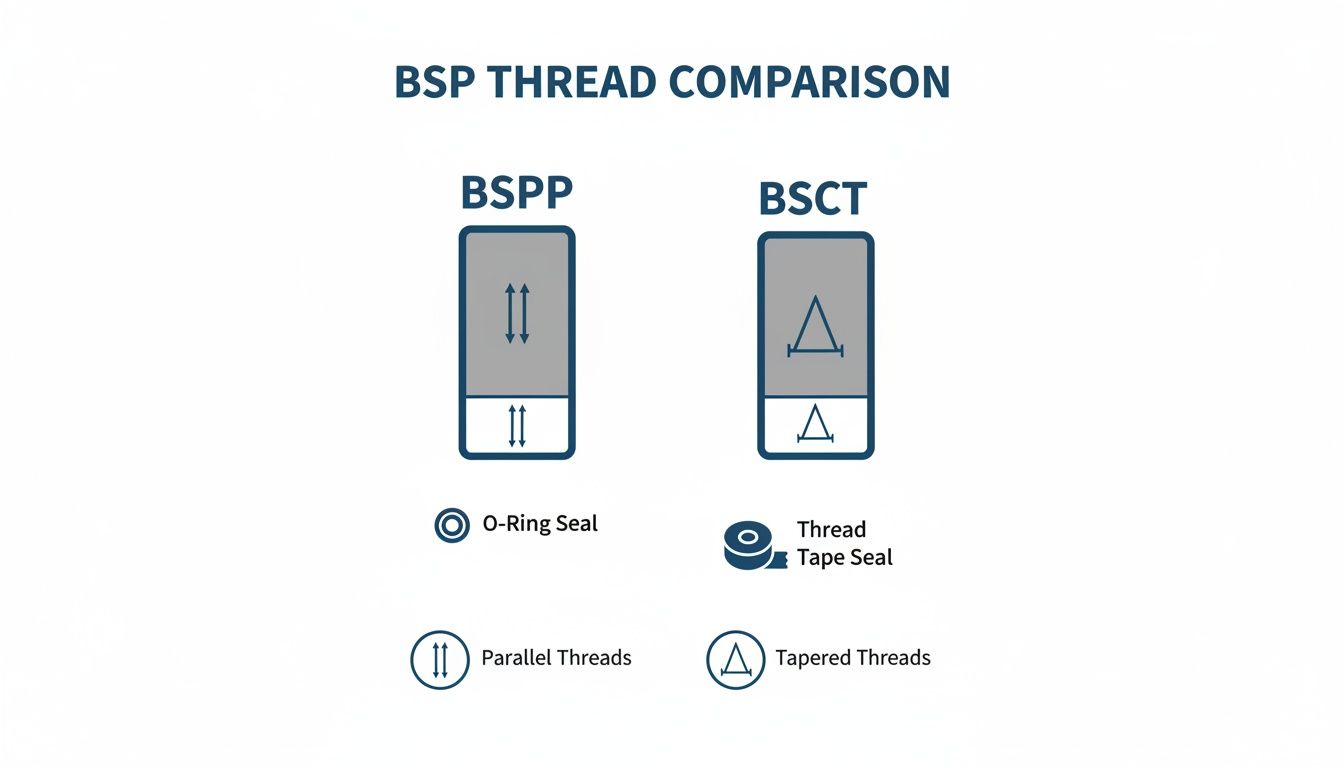

- BSPP (British Standard Pipe Parallel): As the name suggests, these threads are parallel. The seal isn't made by the threads mashing together; instead, a bonded seal or an O-ring gets compressed against a flat face on the port. It's a brilliant design for high-pressure hydraulics because you can take it apart and put it back together multiple times without wrecking the seal.

- BSPT (British Standard Pipe Tapered): This one's different. The thread is conical, and it seals by creating an interference fit as the male and female threads wedge into one another. You’ll pretty much always need a thread sealant, like PTFE tape, to get a truly leak-proof joint.

This whole issue of mismatched standards isn't new. In fact, engineers were debating the clashes between imperial BSP and metric systems way back at the 1901 International Engineering Congress. You can read more about the UK's metric timeline to see just how long this has been going on. This history really drives home why a direct 1/4 BSP to metric connection is impossible and why choosing the right adaptor is so critical for keeping a system safe and sound.

Quick Reference: 1/4 BSP to Metric

When you're on the workshop floor and need a fast, accurate identification, this is the reference you'll want. Getting the 1/4 BSP to metric conversion right is critical, and it's important to remember they're not directly compatible. You can't just screw one into the other.

The core differences in thread pitch, angle, and diameter mean you'll always need a purpose-built adaptor to create a secure, leak-free hydraulic connection.

The image below highlights the key differences between BSPP (Parallel) and BSPT (Tapered) threads, particularly how they seal.

As you can see, BSPP uses an O-ring or bonded seal, which is essential for high-pressure systems. In contrast, the BSPT relies on the taper of its threads, usually with a sealant like PTFE tape, to form the seal.

1/4 BSP to Common Metric Thread Specifications

This table lays out the core specifications for a 1/4 BSP thread and compares them directly with a common metric equivalent, like an M12x1.5. This should help you quickly identify what you're working with and select the correct adaptor.

| Attribute | 1/4 BSP (BSPP & BSPT) | Common Metric Equivalent (e.g., M12x1.5) | Notes for Identification |

|---|---|---|---|

| Outer Diameter (OD) | Approx. 13.16 mm | M12 has a 12 mm OD; M14 has a 14 mm OD. | Grab a set of digital callipers and measure the male thread's crests. The 1/4 BSP will be slightly larger than an M12. |

| Thread Pitch | 19 TPI (1.337 mm per thread) | M12x1.5 has a 1.5 mm pitch. | Use a thread gauge. BSP is measured in threads per inch (TPI), while metric pitch is the distance in mm between threads. |

| Thread Angle | 55 Degrees | 60 Degrees | This fundamental difference in the V-shape of the threads is why they are completely incompatible. |

| Common Adaptor | Male 1/4 BSPP to Female M12x1.5 | Check both the port and the hose ends. | Always select an adaptor that perfectly matches both thread types and their required sealing methods (e.g., O-ring vs. tapered). |

Remember, using the right tools like callipers and a thread gauge takes the guesswork out of identification. These numbers make it clear why a direct connection is impossible and why a dedicated adaptor is your only safe option for mixing BSP and metric systems.

How to Correctly Identify and Measure Threads

Getting thread identification wrong is one of the quickest ways to cause costly leaks and system downtime. It’s a common pitfall, but with the right tools and a bit of practice, you can get it right every time. This is an absolutely essential skill for anyone working on hydraulic systems, especially when you're trying to figure out a 1/4 BSP to metric conversion.

To do the job properly, you'll need two key bits of kit: a decent set of digital callipers and a thread pitch gauge. These tools take the guesswork out of the equation and let you know exactly what you're dealing with.

Step-by-Step Measurement Guide

Here’s the straightforward process I follow on the workshop floor:

Measure the Outer Diameter (OD): Grab your digital callipers and measure across the outside of the male thread. For a 1/4 BSP thread, you should get a reading very close to 13.16 mm. This first measurement is your biggest clue.

Determine the Thread Pitch: Now, use your thread pitch gauge. With BSP threads, you’re looking for the Threads Per Inch (TPI). Just keep trying the leaves of the gauge until one sits perfectly in the threads. A 1/4 BSP fitting will always have 19 TPI. If you were checking a metric thread, the gauge would instead measure the distance in millimetres between each crest.

Identify the Thread Type (Parallel or Tapered): Take a good look at the fitting itself. Does the thread diameter stay the same all the way along? If so, you've got a BSPP (Parallel) thread. If it gets noticeably narrower towards the end, it’s a BSPT (Tapered) thread.

A crucial extra check is to look for a sealing face. If a BSPP fitting is meant to be used with a bonded seal, you'll see a smooth, machined surface at the base where the seal is supposed to sit. This is a dead giveaway for how it's designed to seal.

Following these steps methodically will give you a positive ID. For a more comprehensive look at what's out there, it's worth exploring the different types of hydraulic fittings available. Once you're certain about the BSP and metric components you're working with, you can choose the right adaptor with confidence, knowing you'll get a secure, leak-free connection.

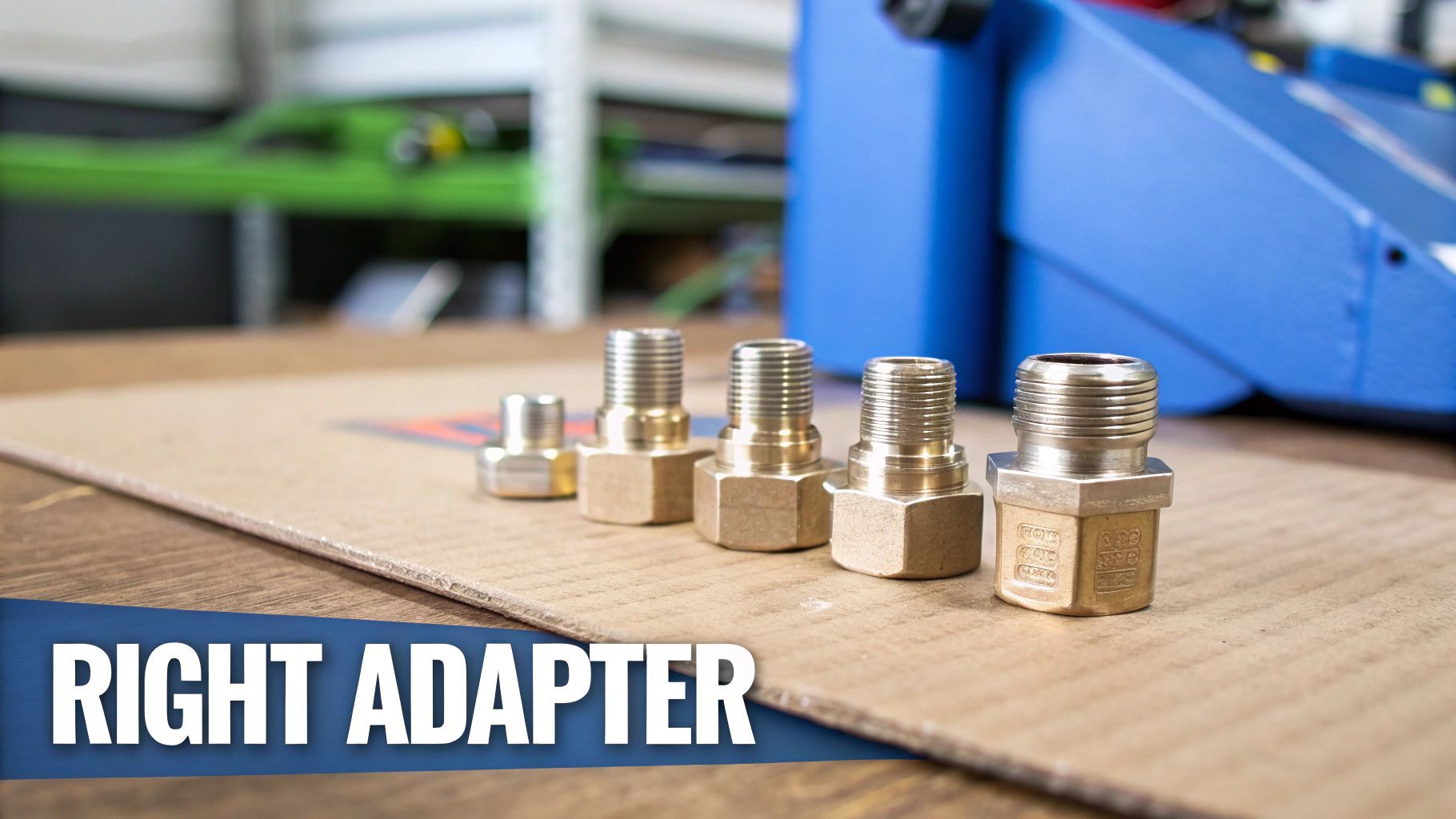

Choosing the Right 1/4 BSP to Metric Adaptor

Picking the right adaptor is the final, and most critical, step when you're converting from 1/4 BSP to metric. Get it wrong, and you're not just looking at a messy leak; you could end up damaging expensive hydraulic components. The right choice always comes down to the specific connection you need to make.

Think of it as a simple matching game where precision is everything. The adaptor has to be a perfect go-between for the male and female threads you're joining. For instance, if you're connecting a male 1/4 BSPT port on a pump to a hose with a female M12x1.5 fitting, you'll need an adaptor with a female 1/4 BSPT end and a male M12x1.5 end.

Materials and Sealing Methods

The adaptor's material is just as important as getting the threads right. High-tensile steel is the industry standard for most hydraulic work because of its fantastic pressure ratings. But if your system is going to be exposed to corrosive fluids or a particularly harsh environment, you’ll be better off opting for stainless steel.

A crucial safety point: always make sure your adaptor's pressure rating meets or, even better, exceeds your system's maximum operating pressure. This is non-negotiable.

Just as critical is understanding how the connection will seal. Different thread types need different sealing methods to stay leak-free under pressure.

- BSPP (Parallel) Ports: These rely on a soft seal. Your adaptor will need either a bonded seal (often called a Dowty washer) or an O-ring that compresses neatly against the flat face of the port.

- BSPT (Tapered) Ports: Here, the seal is made by the interference fit of the threads themselves. You must apply a thread sealant, like PTFE tape or a liquid sealant paste, to the male threads before tightening.

- Metric Ports: Sealing for metric fittings can vary quite a bit. Some use a cutting-edge face seal, others have an O-ring, and some work with a tapered design much like BSPT.

A very common job we see is connecting a modern European hose to an older British power pack. This almost always calls for a specific 1/4 BSP to metric port adaptor, a part that any good specialist supplier will have on the shelf. You can see some examples of these essential hydraulic port adaptors to get an idea of the options. Getting this choice right from the start is the key to a reliable, leak-free system.

For expert advice on finding the perfect adaptor for your specific application, give our team a call on 01724 279508 today, or send us a message.

Common Mistakes When Converting Threads

Even seasoned technicians can make costly mistakes when tackling a 1/4 BSP to metric conversion. Getting it wrong can lead to dangerous, high-pressure leaks and permanently damage expensive components, so it's vital to sidestep these common pitfalls.

One of the biggest mix-ups is confusing BSP with NPT (the American National Pipe Thread standard). At a quick glance, they look alike, but they're fundamentally different. The thread angles (55° for BSP versus 60° for NPT) and pitches don't match up, and trying to force one into the other will destroy the threads on both fittings.

Another surprisingly common error is attempting to jam a metric fitting straight into a BSP port. It might seem obvious not to, but in a rush, people try it. The mismatched diameter and pitch will strip the threads instantly, creating a weak point that's guaranteed to fail under pressure. It's a shortcut that always leads to more work and expense.

Getting the Sealing Method Wrong

Using the wrong sealant is just as bad as using the wrong fitting. Each thread type seals in a specific way, and if you don't respect that, your connection will never be secure.

- Putting PTFE tape on BSPP threads: This is a classic blunder. BSPP (Parallel) threads aren't designed to seal on the threads themselves; they seal using a bonded washer or an O-ring against a flat face. Adding tape actually gets in the way of this mechanism, preventing a proper, leak-proof seal.

- Forgetting sealant on BSPT threads: On the flip side, BSPT (Tapered) threads do seal on the threads. The taper creates an interference fit, but you still need a sealant like PTFE tape or a suitable liquid paste to fill any microscopic voids and guarantee a tight seal.

By keeping these frequent errors in mind, you can adopt a simple "measure twice, fit once" mentality. This discipline ensures you always grab the right adaptor and use the correct sealing method, which is the key to building a reliable and long-lasting hydraulic connection.

For specialist advice or to get your hands on the right adaptors, give us a call on 01724 279508 today or send us a message.

Practical Applications in UK Hydraulic Systems

Knowing the theory behind a 1/4 BSP to metric conversion is one thing, but seeing it in the real world is where it really matters. Across the UK, in sectors like agriculture, plant machinery, and manufacturing, these conversions are an everyday challenge.

Think about retrofitting an older, British-made tractor. You might be installing a modern hydraulic pump, likely sourced from mainland Europe, which will almost certainly have metric ports. To connect it to the tractor's existing BSP hydraulic lines, you need the right adaptor. It's a classic scenario.

Another common example is in industrial power packs. Let's say you're integrating a new, high-efficiency CETOP valve with metric ports into a legacy system built around 1/4 BSP fittings. A precise conversion is absolutely critical here to maintain system integrity and stop high-pressure leaks before they start.

Ensuring Operational Efficiency

Getting these mixed-thread environments right is fundamental to keeping machinery reliable. For anyone specialising in hydraulic gear pumps or building bespoke industrial power packs, dealing with 1/4 BSP to metric conversions is a constant. You simply can't afford compatibility issues.

In fact, mismatched fittings are a notorious risk. They can lead to serious efficiency losses in non-standard units and highlight why you need a skilled team on the job. The whole history of UK metrication has led us to this point where mixed systems are common.

Using the correctly selected adaptors and fittings—like those found in quick release hydraulic couplers—ensures your equipment runs not just efficiently, but safely. It's about preventing the kind of catastrophic failures that incompatible threads can cause.

For expert help with your hydraulic conversions, give us a call on 01724 279508 today, or send us a message.

Need a Hand with Your Hydraulic Conversions?

Figuring out the right fittings for a mixed-thread hydraulic system, especially something like a 1/4 BSP to metric conversion, can be a real headache. It’s a technical minefield, and a wrong move can quickly lead to leaks, costly downtime, and even damage to your machinery. This is exactly where getting some expert advice makes all the difference – it cuts out the guesswork and ensures the job is done right, first time.

Here at MA Hydraulics, we deal with these challenges every single day. We keep a massive stock of high-quality fittings and adaptors on the shelf, ready to go, providing solid solutions for even the most unusual conversions. You'll find top-tier brands known for standing up to the pressure.

More Than Just Parts on a Shelf

Our team is here to be your technical partner, not just a supplier. We can help you cross-reference components and recommend the correct fittings for whatever you're working on. It doesn’t matter if you need one adaptor for a quick repair in the field or you're plumbing in a complete bespoke hydraulic system from the ground up; our experience ensures you get total compatibility and a safe setup.

We take a lot of pride in helping our customers find the right part quickly, saving them both time and money.

For practical advice and access to our full range of hydraulic solutions, give our team a call today on 01724 279508, or send us a message through the website.

Answering Your Questions About Thread Conversion

When you're dealing with a 1/4 BSP to metric conversion, a few practical questions almost always come up. Getting these details right is crucial for avoiding costly mistakes and making sure your hydraulic system runs both safely and efficiently. Let's tackle some of the most common queries we see.

Can I Use a 1/4 BSP Bolt in a Metric Threaded Hole?

In a word, no. It's a common temptation but one you must avoid. BSP and metric threads are fundamentally incompatible due to their different profiles and pitches.

A 1/4 BSP thread is designed with 19 threads per inch (TPI) and a 55-degree flank angle. Compare that to a common metric equivalent like an M12x1.5, which has a 1.5mm pitch and a 60-degree angle. Trying to force them together is a recipe for disaster; it will strip the threads on both components, causing permanent damage and making a secure, high-pressure seal impossible.

What Is the Pressure Rating of a BSP to Metric Adaptor?

There's no single answer here, as the pressure rating is dictated by the adaptor's material, design, and overall manufacturing quality. In the world of hydraulics, high-tensile steel is the norm, and you'll find that many adaptors are rated for pressures well over 300 bar.

However, you should never assume. Always consult the manufacturer’s technical data sheet to confirm the adaptor meets or exceeds the maximum operating pressure of your system. It's a simple check that prevents catastrophic failure.

Is BSPP or BSPT Better for High-Pressure Hydraulics?

For just about any modern high-pressure hydraulic system, BSPP (Parallel) is the clear winner and the recommended standard. It provides a far more reliable seal that's also reusable.

The secret is in how it seals: a bonded washer or an O-ring is compressed against a smooth, machined face. This creates an incredibly robust, leak-proof connection that stands up to intense pressure and vibration. BSPT, on the other hand, relies on the threads themselves forming an interference fit, which is much less dependable for the dynamic forces found in high-pressure hydraulics.

If you're still working through the details or need the right components for your setup, the experienced team at MA Hydraulics Ltd is here to help.

Phone 01724 279508 today, or send us a message online.